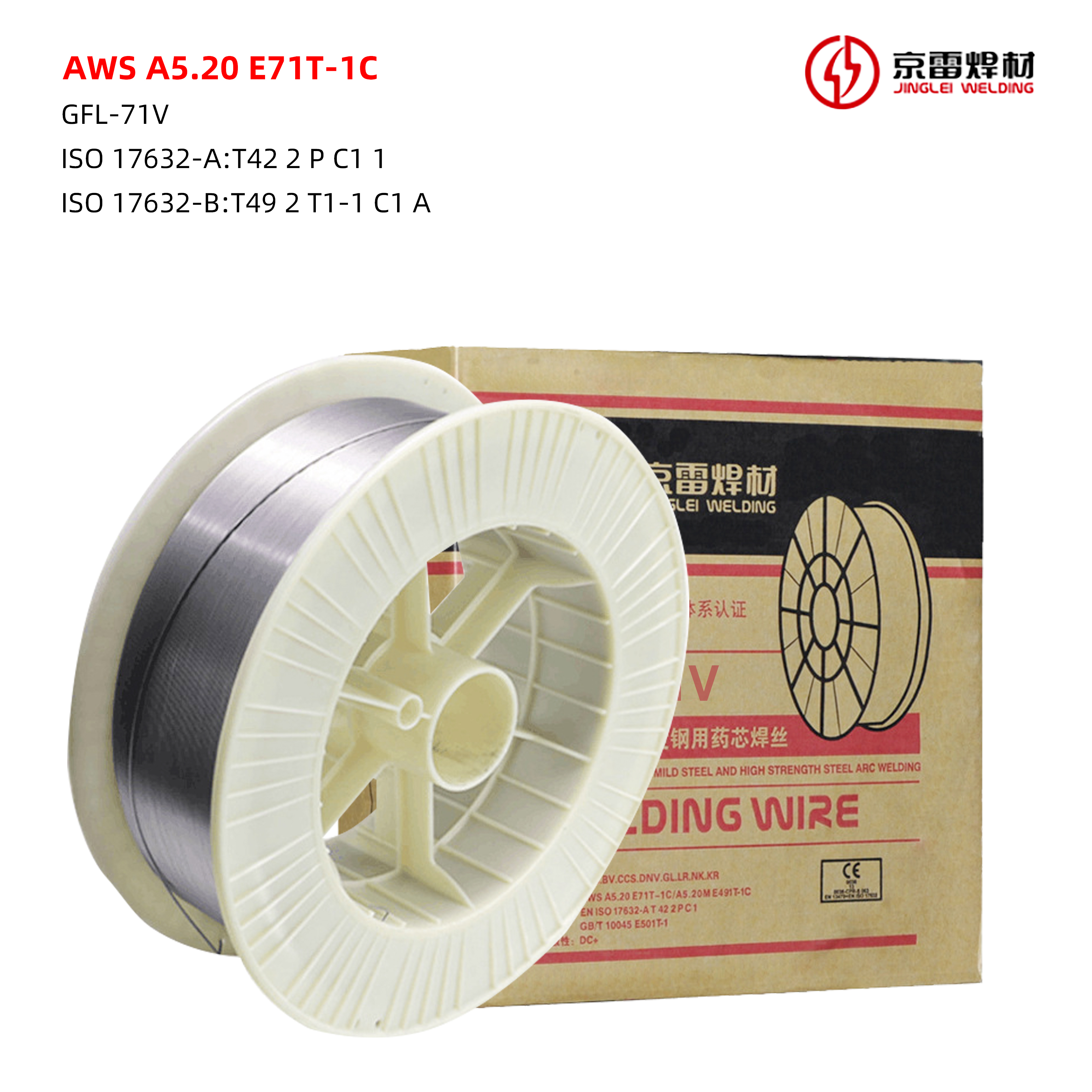

High Carbon steels CO2 Protect E70T-1C Flux cored wire welding accessories

Application & Standard

1. Suitable for flat welding and fillet welding of ships, Bridges, machinery, vehicles and steel structures.

2. The standard we met:

GB/T10045 T49 2 T15-0 C1 A, AWS A5.20 E70T-1C & A5.20M E490T-1C, ISO17632-A:T 42 2 R C1 3, ISO 17632-B:T49 2 T15-1 C1 A JIS Z3313 T492T15-1CA-U

3.It can be used for welding of cast steel or medium thick plate.

Features

1. The arc is soft and stable, less splash, beautiful forming, good slag removal, less soot, with excellent welding process performance.

2. Excellent resistance to priming, good resistance to porosity and crack.

Company & Factory

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | 0.18 | 2.00 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| AWS RULES | 0.12 | 1.75 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| EXAMPLE VALUE | 0.045 | 1.45 | 0.50 | 0.02 | 0.02 | 0.01 | 0.012 | 0.006 | 0.01 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 390 | 490-670 | AW | 27/-20 | 18 | ||||

| AWS RULES | 390 | 490-670 | AW | 27/-20 | 22 | ||||

| EXAMPLE VALUE | 500 | 575 | AW | 60/-20 | 27 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.2 | 1.4 | 1.6 | ||||

| VOLT | 23-34 | 24-42 | 25-46 | ||||

| AMP | 150-320 | 170-400 | 200-450 | ||||

| MM | 15-20 | 15-20 | 18-25 | ||||

| L/MIN | 15-25 | 15-25 | 15-25 |

NOTE:

CO2 Protect gas, pre heating :150±15℃

CERTIFICATION AUTHORITY:ABS/BV/CCS/DNV/GL/LR/NK/CE/JIS

TYPICAL CASES

Certificates

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | 0.18 | 2.00 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| AWS RULES | 0.12 | 1.75 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| EXAMPLE VALUE | 0.045 | 1.45 | 0.50 | 0.02 | 0.02 | 0.01 | 0.012 | 0.006 | 0.01 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 390 | 490-670 | AW | 27/-20 | 18 | ||||

| AWS RULES | 390 | 490-670 | AW | 27/-20 | 22 | ||||

| EXAMPLE VALUE | 500 | 575 | AW | 60/-20 | 27 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.2 | 1.4 | 1.6 | ||||

| VOLT | 23-34 | 24-42 | 25-46 | ||||

| AMP | 150-320 | 170-400 | 200-450 | ||||

| MM | 15-20 | 15-20 | 18-25 | ||||

| L/MIN | 15-25 | 15-25 | 15-25 |

NOTE:

CO2 Protect gas, pre heating :150±15℃

CERTIFICATION AUTHORITY:ABS/BV/CCS/DNV/GL/LR/NK/CE/JIS