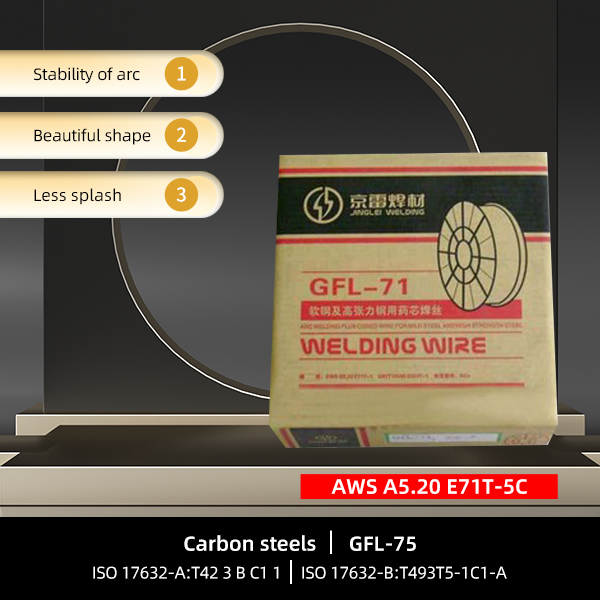

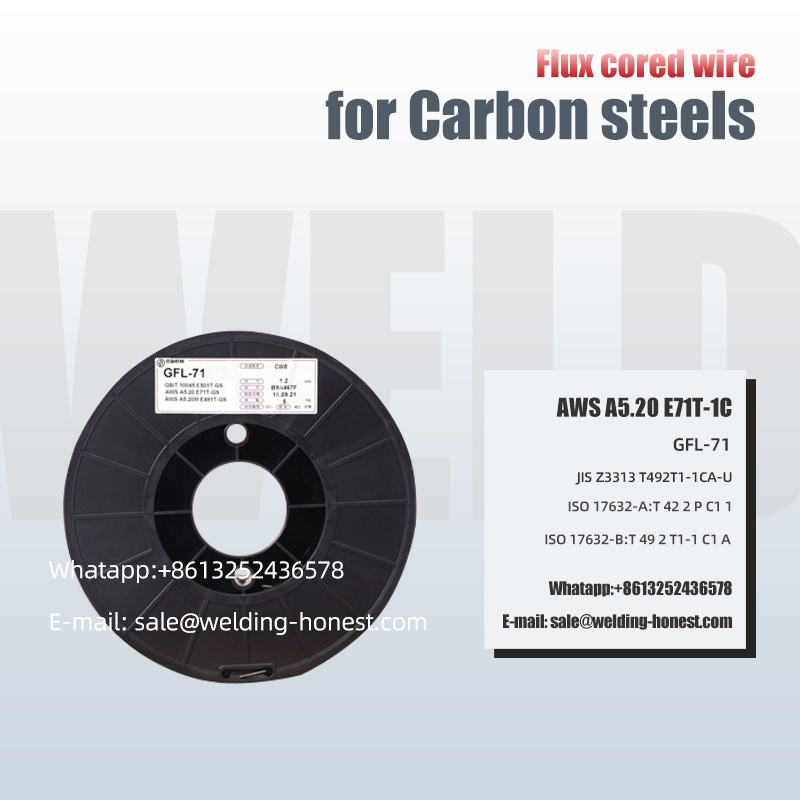

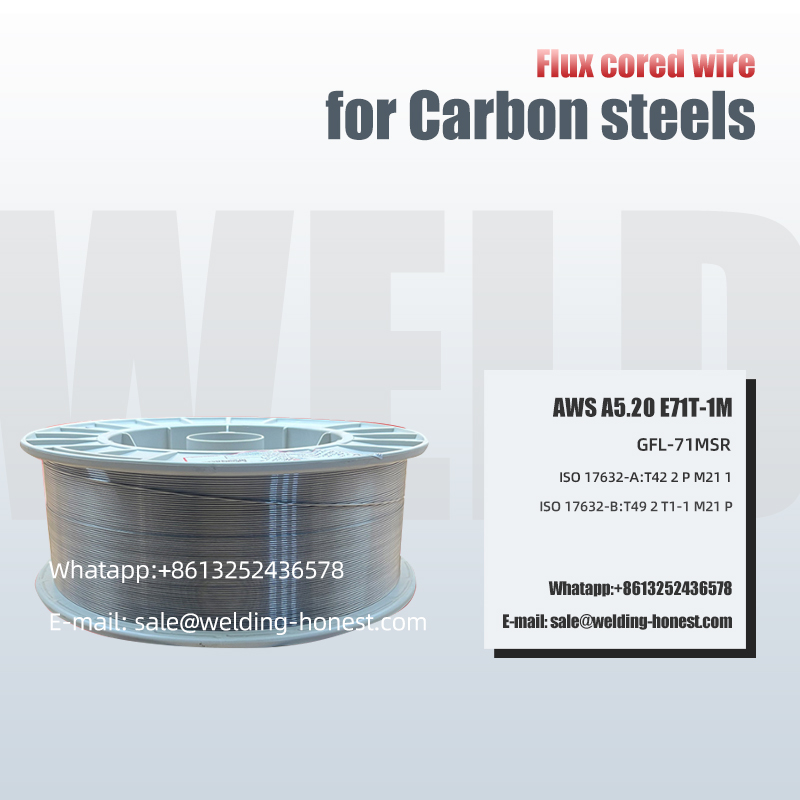

High Carbon steels Flux cored wire E71T-5C welding makings

Application

Suitable for pressure vessel, shipbuilding, offshore platform, steel structure welding.

The standard we met: GB/T10045 T 49 3 T5-1 C1 A , AWS A5.20 E71T-5C & A5.20M E491T-5C, ISO17632-A:T42 3 B C1 1, ISO 17632-T493T5-1C1-A.

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | 0.18 | 2.00 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| AWS RULES | 0.12 | 1.75 | 0.90 | 0.20 | 0.50 | 0.30 | 0.03 | 0.03 | 0.08 |

| EXAMPLE VALUE | 0.080 | 1.50 | 0.08 | 0.01 | 0.48 | 0.01 | 0.010 | 0.002 | 0.01 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 390 | 490-670 | AW | 27/-30 | 18 | ||||

| AWS RULES | 390 | 490-670 | AW | 27/-30 | 22 | ||||

| EXAMPLE VALUE | 450540 | 550 | AW | 80/-30 | 26 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.2 | ||||||

| VOLT | 20-25 | ||||||

| AMP | 160-250 | ||||||

| MM | 15-25 | ||||||

| L/MIN | 20-25 | ||||||

Peculiarity

The mechanical properties of the fused metal are stable.

Crack resistance and pore resistance are good

The pass rate of X-ray is high.

Show details

Good crack resistance and porosity resistance

X-Ray has a high pass rate

About us

Factory fioor display

Application case

Sinopec Refinery project

Zhangjiagang Hanzhong Cryogenic Technology Co., LTD. Low temperature storage and transportation container

Actual factory shooting

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | 0.18 | 2.00 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| AWS RULES | 0.12 | 1.75 | 0.90 | 0.20 | 0.50 | 0.30 | 0.03 | 0.03 | 0.08 |

| EXAMPLE VALUE | 0.080 | 1.50 | 0.08 | 0.01 | 0.48 | 0.01 | 0.010 | 0.002 | 0.01 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 390 | 490-670 | AW | 27/-30 | 18 | ||||

| AWS RULES | 390 | 490-670 | AW | 27/-30 | 22 | ||||

| EXAMPLE VALUE | 450540 | 550 | AW | 80/-30 | 26 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.2 | ||||||

| VOLT | 20-25 | ||||||

| AMP | 160-250 | ||||||

| MM | 15-25 | ||||||

| L/MIN | 20-25 | ||||||

Write your message here and send it to us