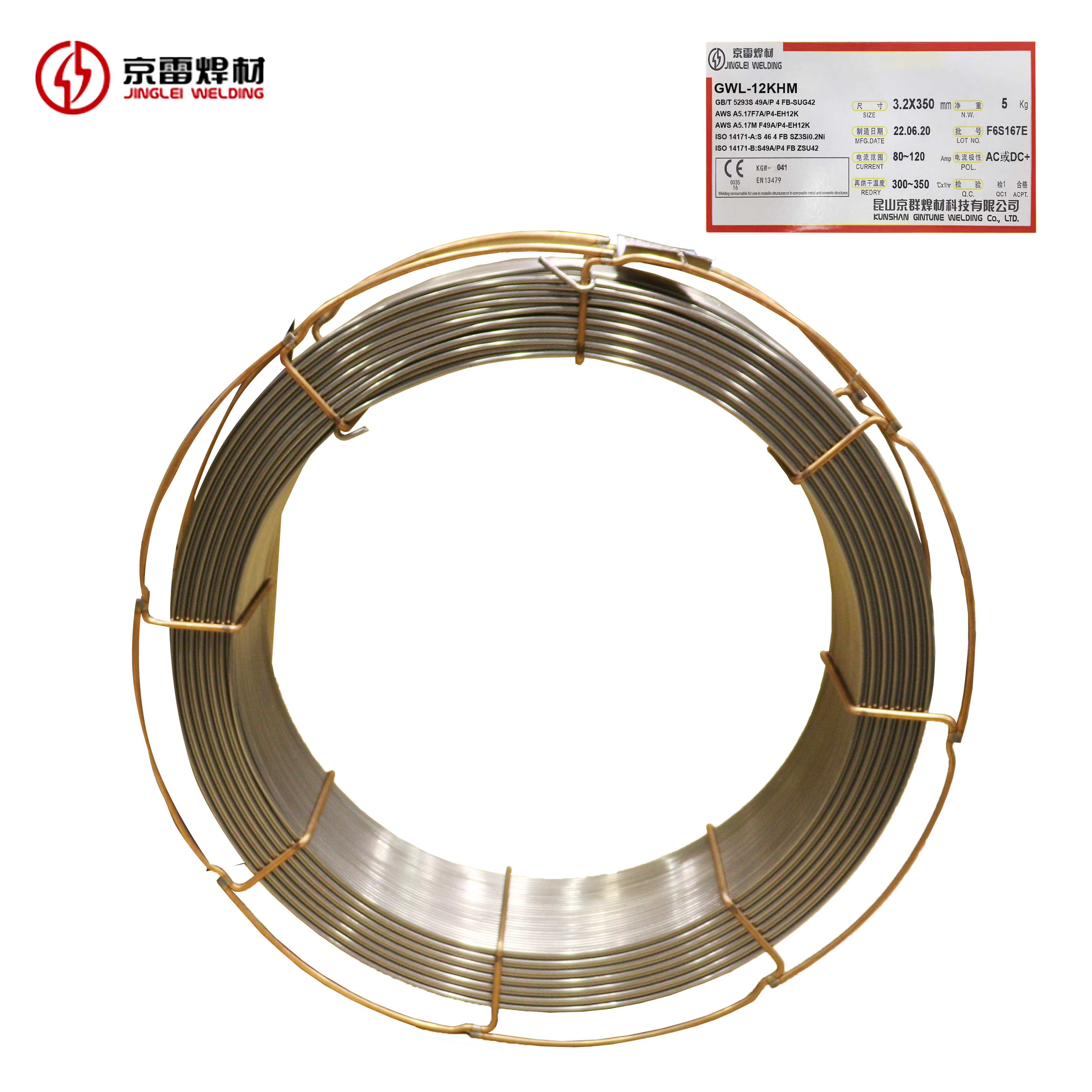

High Carbon steels SAW welding wire F7A/P4-EH12K and welding flux weld fabrication accessories

Used for -40C impact required environment, shipbuilding, pipeline, pressure vessels and other equipment welding.

What are the characieristics?

●Submerged arc welding wire for 480MPa grade high strength steel: welding with GXL-125 flux, stable arc combustion during welding, easy slag removal, beautiful welding pass forming.

●The weld metal has good mechanical properties and high pass rate of X - ray.

Product Parameter

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Si | Mn | P | S | Ni | Mo | Other |

| GB/T RULES | 0.053 | 0.75 | 1.87 | 0.01 | 0.003 | 0.17 | 0.14 | - |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | ELONGATION % | IMAPACT VALUE J/℃ | Heat treatment °C*h | ||||

| GB/T RULES | 493 | 593 | 28 | 80/-40 | 620*6 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 3.2 | 4.0 | 5.0 | |||||

| Voltage(Volt) | 28-32 | 28-32 | 28-34 | |||||

| Electricity(Amp) | 400-550 | 500-650 | 500-750 | |||||

| Speed(mm/min) | 300-420 | 400-480 | 400-580 | |||||

| Dry stretch length(mm) | 22-26 | 30-34 | 38-42 | |||||

Mode of transportation

●Motor transport

●Shipping

Our warehouse

We participate in the program

●Polypropylene reactor

●Welding materials for aluminum alloys

Our products to the world

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Si | Mn | P | S | Ni | Mo | Other |

| GB/T RULES | 0.053 | 0.75 | 1.87 | 0.01 | 0.003 | 0.17 | 0.14 | - |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | ELONGATION % | IMAPACT VALUE J/℃ | Heat treatment °C*h | ||||

| GB/T RULES | 493 | 593 | 28 | 80/-40 | 620*6 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 3.2 | 4.0 | 5.0 | |||||

| Voltage(Volt) | 28-32 | 28-32 | 28-34 | |||||

| Electricity(Amp) | 400-550 | 500-650 | 500-750 | |||||

| Speed(mm/min) | 300-420 | 400-480 | 400-580 | |||||

| Dry stretch length(mm) | 22-26 | 30-34 | 38-42 | |||||

Write your message here and send it to us