I. Overview

With the rapid development of machinery industry production, welded structures such as modern engineering and pressure vessels are developing towards increasingly large and lightweight trends. The requirements for steel strength grades are getting higher and higher, not only requiring good comprehensive mechanical properties, but also good processability, weldability and crack resistance.

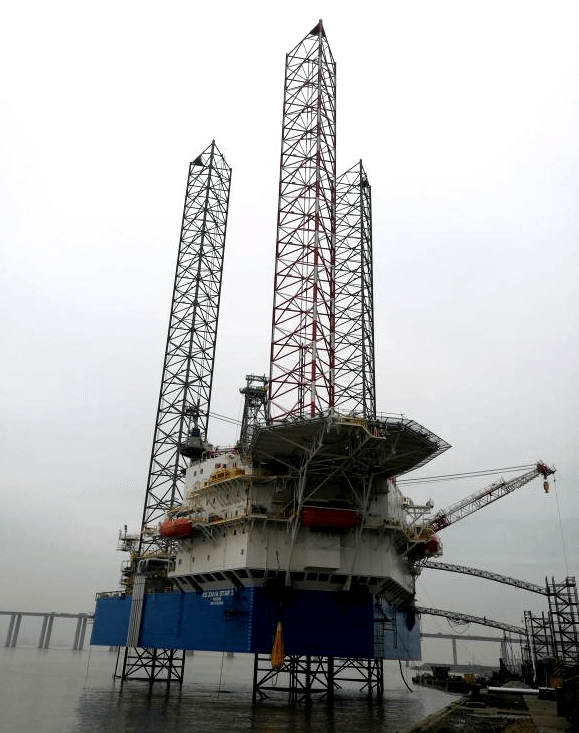

Q690 steel belongs to high-strength welded structural steel, where Q stands for yield, and 690 means the yield strength level is 690MPa. 690MPa grade steel has high yield and tensile strength, and is widely used in coal mining machinery, construction machinery, marine engineering, offshore platforms, pressure vessels, etc., requiring steel to have high yield strength and fatigue limit, good impact toughness, Cold formability and excellent weldability.

2.Brief introduction of Q690 steel plate

|

International Q690 steel grade |

Q690A |

Q690B |

Q690C |

Q690D |

Q690E |

Q690F |

|

Feather |

Hot rolled |

Quenching + tempering (quenched and tempered state) |

||||

|

Impurity content |

Higher P/S |

low P/S |

Minimum P/S |

|||

|

Shock Requirements |

NO |

Normal temperature shock |

0℃ |

-20℃ |

-40℃ |

-60℃ |

However, at present, the 690MPa steel plate for domestic pressure vessels is mainly based on the European standard EN10028-6, and the relevant properties are briefly listed in the following table:

|

Yield 690MPA steel for European standard pressure equipment |

P690Q |

P690QH |

P69QL1 |

P69QL2 |

|

Feather |

fine grain quenched and tempered steel |

|||

|

strength requirements |

Yield≥690MPa(plate thickness≤50mm) Tensile770-940MPa |

|||

|

Impurity content |

P≤0.025%,S≤0.015% |

P≤0.02%,S≤0.010% |

||

|

Shock Requirements |

20℃≥60J |

20℃≥60J |

0℃≥60J |

-20℃≥40J |

|

0℃≥40J |

0℃≥40J |

-20℃≥40J |

-40℃≥27J |

|

|

-20℃≥27J |

-20℃≥27J |

-40℃≥27J |

-60℃≥27J |

|

|

Main application areas |

Pressure-bearing structures or pressure vessels with low impact toughness requirements |

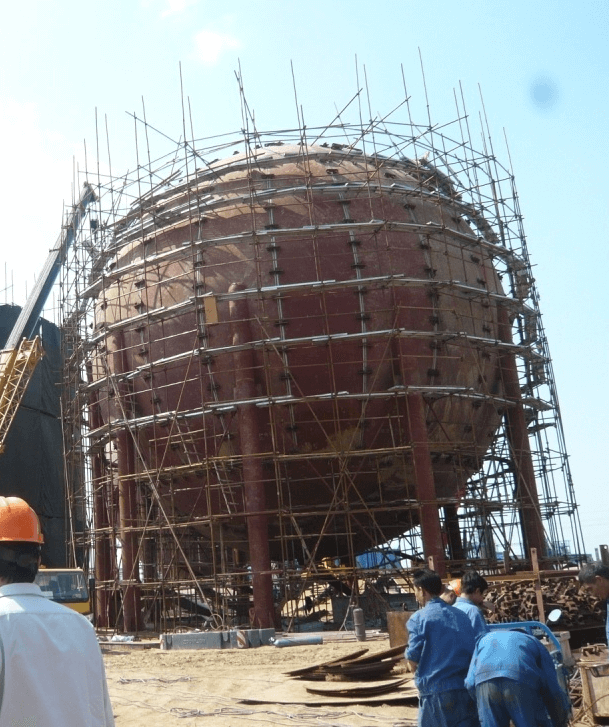

Spherical tank with high technical requirements |

Liquefied gas marine liquid tank |

|

As a steel plate for storage tanks and pressure capacity, it must have good strength and toughness, cold bending performance and low crack sensitivity. Although the quenched and tempered Q690 steel has a lower carbon equivalent and excellent comprehensive properties, it still has a certain hardening tendency compared with other 50/60kg pressure vessel steels, and post-weld heat treatment is required. However, a large number of experimental studies have shown that for Q690 steel welding consumables, the low-temperature impact toughness will be significantly deteriorated after stress relief heat treatment, and with the increase of heat treatment temperature and the decrease of impact temperature, the deterioration of welding consumable toughness will be more obvious. Therefore, it is of great practical significance to develop high-strength, high-impact toughness, and heat-treatable welding rods for Q690 steel to successfully apply Q690 steel to pressure-bearing equipment, reduce steel materials, and reduce manufacturing costs.

3.Brief introduction of our Q690 steel welding rod

| Item | Standard | Skin type | Polarity | main features |

| GEL-118M | AWS A5.5 E1108MISO 18275-BE7618-N4M2A | Iron powder low hydrogen type | DC+/AC | High strength, low hydrogen, high deposition efficiency, stable mechanical properties, excellent low temperature impact toughness at -50°C, and good impact toughness at -40°C after heat treatment |

| GEL-758 | AWS A5.5 E11018-GISO 18275-BE7618-G A | Iron powder low hydrogen type | DC+/AC | Ultra-low hydrogen, high deposition efficiency, high toughness (-60℃≥70J), good impact toughness at -40/-50℃ after heat treatment |

| GEL-756 | AWS A5.5 E11016-GISO 18275-BE7616-G A | Low hydrogen potassium type | AC/DC+ | Ultra-low hydrogen, AC/DC+ dual-purpose, high impact toughness (-60℃≥70J), good impact toughness at -50/-60℃ after heat treatment |

4.Q690 steel welding rod mechanical performance display

|

Item |

As-welded mechanical properties |

||||||

|

Yield MPA |

Tensile MPA |

Extend % |

Impact property J/℃ |

Radiographic test |

Diffusible hydrogen Ml/100g |

||

|

-50℃ |

-60℃ |

||||||

|

AWS A5.5 E11018M |

680- 760 |

≥760 |

≥20 |

≥27 |

- |

I |

- |

|

ISO 18275-B E7618-N4M2A |

680- 760 |

≥760 |

≥18 |

≥27 |

- |

I |

- |

|

GEL-118M |

750 |

830 |

21.5 |

67 |

53 |

I |

3.2 |

|

AWS A5.5 E1101X-G |

≥670 |

≥760 |

≥15 |

- |

- |

I |

- |

|

ISO 18275B E761X-GA |

≥670 |

≥760 |

≥13 |

- |

- |

I |

- |

|

GEL-758 |

751 |

817 |

19.0 |

90 |

77 |

I |

3.4 |

|

GEL-756 |

764 |

822 |

19.0 |

95 |

85 |

I |

3.6 |

Illustrate:

1. The "X" marked in red font in the American Standard and European Standard represents the type of drug skin.

2. GEL-758 corresponds to E11018-G and ISO 18275-B E7618-G A in AWS and ISO standards respectively.

3. GEL-756 corresponds to E11016-G and ISO 18275-B E7616-G A in AWS and ISO standards respectively.

Mechanical properties of Q690 steel welding rod in heat treatment state

|

Item |

Mechanical properties of heat treated state |

||||||

|

Yield MPA |

Tensile MPA |

Extend % |

Impact property J/℃ |

Heating ℃*h |

|||

|

-40℃ |

-50℃ |

-60℃ |

|||||

|

Project goal |

≥670 |

≥760 |

≥15 |

≥60 |

≥52 |

≥47 |

570*2 |

|

GEL-118M |

751 |

827 |

22.0 |

85 |

57 |

- |

570*2 |

|

GEL-758 |

741 |

839 |

20.0 |

82 |

66 |

43 |

570*2 |

|

GEL-756 |

743 |

811 |

21.5 |

91 |

84 |

75 |

570*2 |

Illustrate:

1. AWS and ISO related standards have no heat treatment performance requirements for the above products. The above heat treatments are summarized based on the technical conditions of most customers and are for reference only.

2. GEL-118M has excellent impact toughness at -40°C after heat treatment, and the impact deterioration at -50°C is more obvious.

3. After heat treatment, GEL-758 has excellent impact toughness at -40°C, good impact toughness at -50°C, and obvious deterioration at low temperature at -60°C.

4. The low-temperature impact toughness deterioration of GEL-756 after heat treatment is relatively small, and the low-temperature toughness at -60°C is still good.

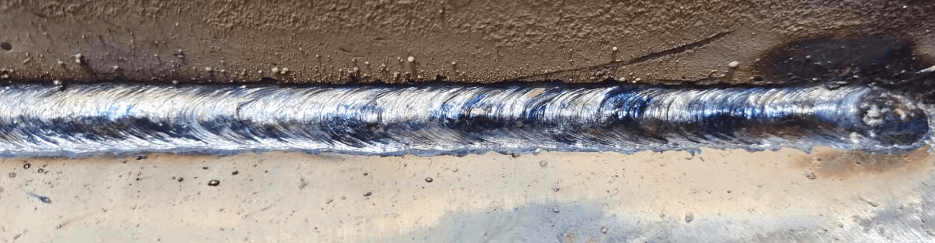

Weldability demonstration of Q690 steel welding rod

1.Flat fillet welding (φ4.0mm)

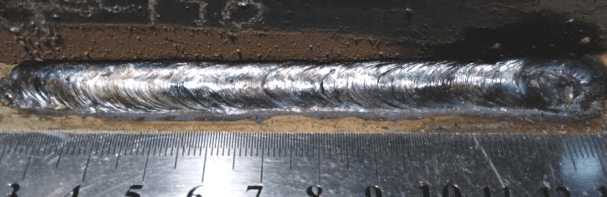

GEL-118M flat fillet welding before and after slag removal (DC+)

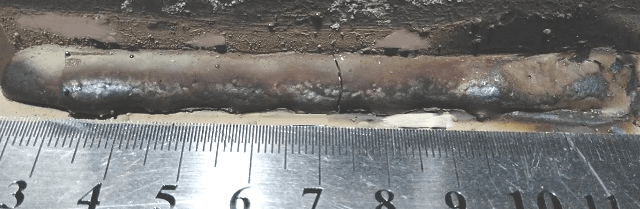

Before and after GEL-758 flat fillet welding slag removal (DC+)

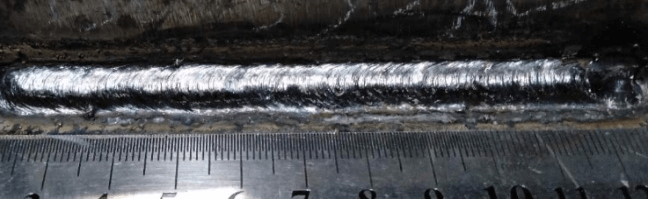

GEL-756 flat fillet welding before and after slag removal (AC)

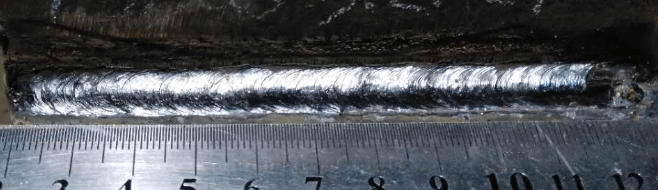

GEL-756 flat fillet welding before and after slag removal (DC+))

Q690 steel welding rod welding precautions

1. Storage of welding consumables:

Welding consumables are recommended to be stored under constant temperature and dry conditions, and placed on pallets or shelves, avoiding direct contact with walls and ground.

2. Preparation before welding:

Thoroughly remove moisture, rust, oil stains, etc. on the surface of the base material, and avoid surface moisture or exposure to rain and snow.

3. Windproof measures:

When welding, it should be ensured that the maximum wind speed at the welding place does not exceed 2m/s. Otherwise, protective measures should be taken.

4. Preheating:

It is recommended to use electric heating equipment to heat the workpiece to above 150°C before welding. Even before tack welding, it should be preheated to above 150°C.

5. Layer and road temperature control:

During the whole welding process, the interpass temperature should not be lower than the preheating temperature, and the recommended pass temperature is 150-220°C.

6. Hydrogen removal after welding:

After the weld seam is welded, immediately increase the temperature of the electric heating to 250 ℃ ~ 300 ℃, keep it warm for 2 to 4 hours, and then cool slowly.

① If the thickness of the workpiece is ≥50mm, the holding time should be extended to 4-6 hours, and then cooled slowly.

② Under the conditions of large thickness and large restraint, one more dehydrogenation can be added after welding to 1/2 thickness, and slowly cooled to the interpass temperature.

7. Floor layout:

It is recommended to use multi-layer and multi-pass welding, and the welding speed should be kept at a constant speed.

More information send to E-mail: export@welding-honest.com

Post time: Jan-10-2023