Low-Alloy Steels Manual Electrode E7018-C2L HEC – three, Haiyang MSR welding wire coil

The main composition is 3.5%Ni steel, low hydrogen potassium type hand welding rod, at -100°C operating temperature, its melting the metal coated impact toughness is excellent

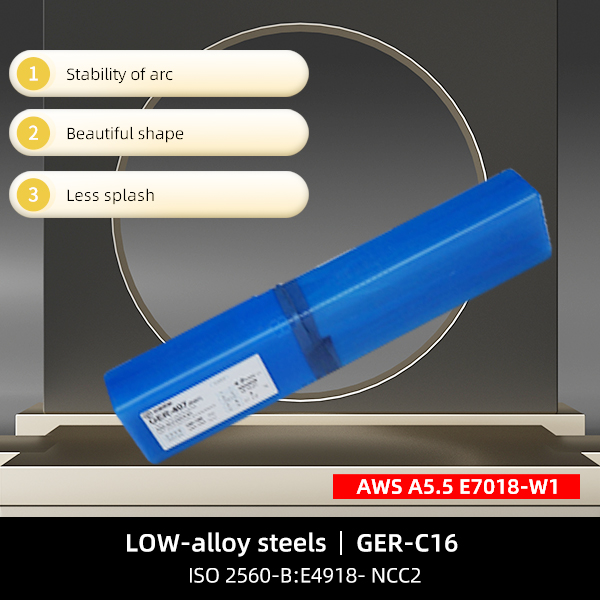

Stable arc, less splash, good molding, easy slag removal

X-Ray performance is excellent

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Si | Mn | P | S | Ni | Cr | Mo | Other | |

| GB/T RULES | 0.032 | 0.18 | 0.66 | 0.004 | 0.003 | 3.58 | 0.031 | 0.009 | - | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | Elongation(%) | IMAPACT VALUE J/℃ | Heat treatment °C*h | |||||

| GB/T RULES | 485 | 565 | 27 | 67/-100 | 620*1 | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY (Amp) |

H/W | 70-100 | 100-140 | 140-180 | 180-230 | ||||

| O/W | 60-90 | 90-130 | 120-160 | - | |||||

Sino-russian eastern front

Haiyang Nuclear Power Plant

-

400,000 tons ore carrier

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Si | Mn | P | S | Ni | Cr | Mo | Other | |

| GB/T RULES | 0.032 | 0.18 | 0.66 | 0.004 | 0.003 | 3.58 | 0.031 | 0.009 | - | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | Elongation(%) | IMAPACT VALUE J/℃ | Heat treatment °C*h | |||||

| GB/T RULES | 485 | 565 | 27 | 67/-100 | 620*1 | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY (Amp) |

H/W | 70-100 | 100-140 | 140-180 | 180-230 | ||||

| O/W | 60-90 | 90-130 | 120-160 | - | |||||

Write your message here and send it to us