Featured Products

-

Low MOQ for Wholesale High Quality Custom Us/National/ Force/Marine Corps Metal Souvenir Challenge Coin

Nickel-based alloy welding wire has good performance of resistance to active gas, caustic medium, corrosion resistance to reducing acid medium, and has high strength, good plasticity, cold and hot deformation and processing and welding characteristics, therefore, widely used in petrochemical, metallurgy, atomic energy, marine development, aviation, aerospace and other industries, to solve the general stainless steel and other metals, non-metallic materials can not solve the engineering corrosion problem, is a very important corrosion-resistant metal material. Nickel-based alloys refer to alloys that are nickel-based and contain alloying elements and can resist corrosion in some media. When classified by its chemical composition, there are mainly nickel, nickel-copper alloys, nickel-molybdenum (nickel-molybdenum ferrolybdenum) alloys, nickel-chromium (nickel-chromium-iron) alloys, nickel-chromium-molybdenum (including nickel-chromium-molybdenum alloys and nickel-chromium-molybdenum copper alloys) and nickel-iron chromium (both iron-nickel-based alloys) and other categories. Pure nickel welding wire ERNi-1 is used to weld 200, 201 nickel alloy and nickel-plated steel plate; welding of steel and nickel dissimilar materials; Surface overlay welding of steel. Nickel-copper welding wire ERNiCu-7 Monel 400 alloy itself welding; and the welding of Monel 400 alloy with steel; Used for surfacing of steel. Nichrome welding wire ERNiCrFe-3 is used for welding dissimilar material welding of creep-resistant joints; – Welding of austenitic, ferritic steels and high nickel alloys, welding of alloy steels containing 9% nickel Nichrome welding wire ERNiCrFe-7 is used for welding alloys and surfacing welding of steel, especially suitable for the construction of nuclear reactors. Welding of nickel-chromium-molybdenum welding wire ERNiCrMo-3 INCONEL625, INCONEL825, INCONEL25-6Mo and MONEL400 alloys; – Welding between ultra-high strength austenitic steel and INCOLOY020 alloy; Welding between nickel-based alloys and stainless steel dissimilar materials; Hardfacing of steel

-

Super Lowest Price Cobalt Base Alloy Welding Rod, Cobalt 6

Being supported by an highly developed and specialist IT team, we could provide technical support on pre-sales & after-sales assistance for Super Lowest Price Cobalt Base Alloy Welding Rod, Cobalt 6, As an experienced group we also accept tailored orders. The main aim of our corporation is always to develop a satisfying memory for all shoppers, and set up a long-term win-win business partnership. Being supported by an highly developed and specialist IT team, we could provide technical su... -

China OEM Welding Rod Electrode E7018 E7016

To create much more benefit for shoppers is our enterprise philosophy; client growing is our working chase for China OEM Welding Rod Electrode E7018 E7016, The principle of our organization would be to offer high-quality solutions, professional support, and honest communication. Welcome all good friends to place trial purchase for developing a long-term company relationship. To create much more benefit for shoppers is our enterprise philosophy; client growing is our working chase for China We... -

factory Outlets for Andeli Welding Rod Tungsten Electrodes 1.6/2.0/2.4/3.2mm Wt20/Wc20/Wl20/Wl15/Wz8/Wp

GEH-547 is a hand electrode for metal surface valve surfacing under the Chinese GB/T984 EDCrNi-A-15 standard. It is mainly used for the valves and other sealing parts of high-rise boiler installations in power stations under 570℃. Surfacing welding is welding a special alloy surface at any part of the workpiece, its purpose is to improve the wear resistance, corrosion resistance and heat resistance of the working surface, in order to reduce the cost, improve the comprehensive performance and service life, with this function of the electrode for surfacing wear-resistant electrode, also known as surfacing electrode.

-

High Quality rods for IQF Frozen Atlantic rod Portion

GB/T8110 G55A 4 CA/M21 S12

AWS A5.28 ER80S-G

A5.28M ER55S-G

ISO 14341-A

ISO 14341-B:G55A4 C1/M21 S16

-

China Gold Supplier for Atlantic Brand Stainless Steel Welding Wire 3.2mm Aws E70T-1C

USA E70T-1 is a flux cored wire for single or multi-pass welds on mild steels and certain low alloy steels. USA E70T-1 is noted for its low spatter generation, high disposition rate and ease of slag removal when used for flat and fillet welds of medium and heavy thickness plates. It has been designed to be used with 100% CO2 or 75-80% Argon + balance CO2 mixed shield gas

-

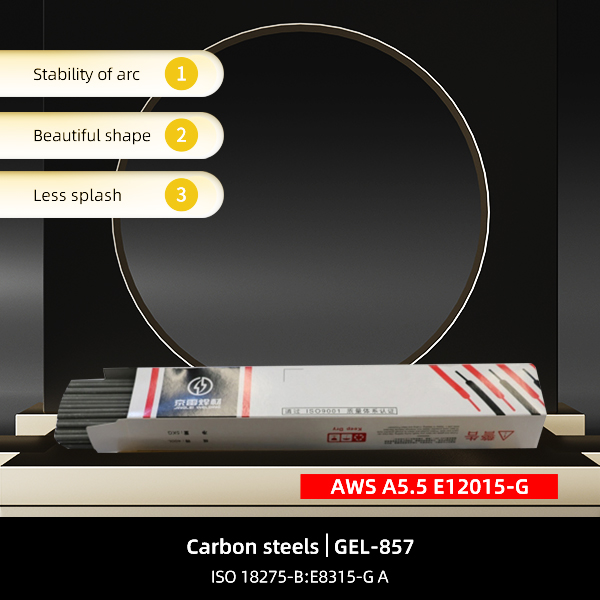

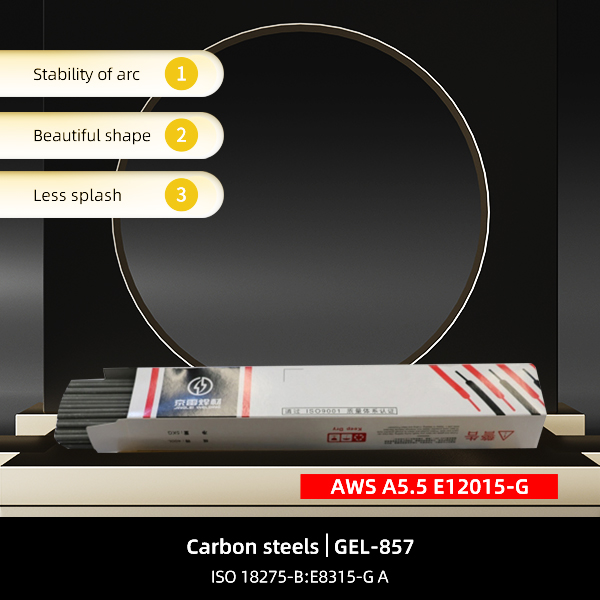

Best-Selling Hot Sale Alloy Steel Welding Electrodes E12015-G

GB/T32533 E8315-G

AWS A5.5 E12015-G

A5.5M E8315-G

ISO 18275-B:E8315-G A

Whatapp:+8613252436578

E-mail: sale@welding-honest.com

-

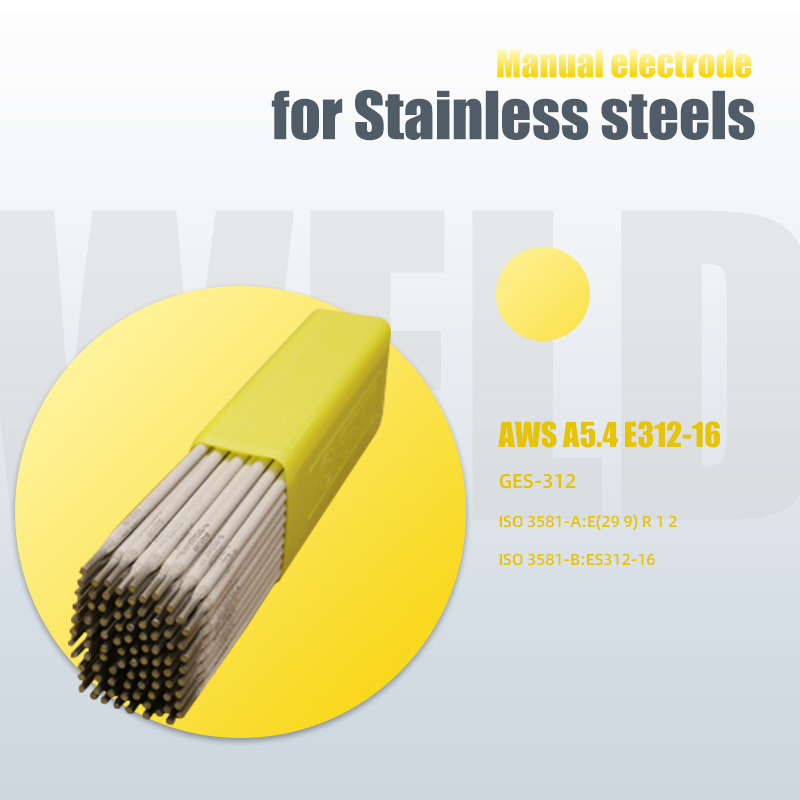

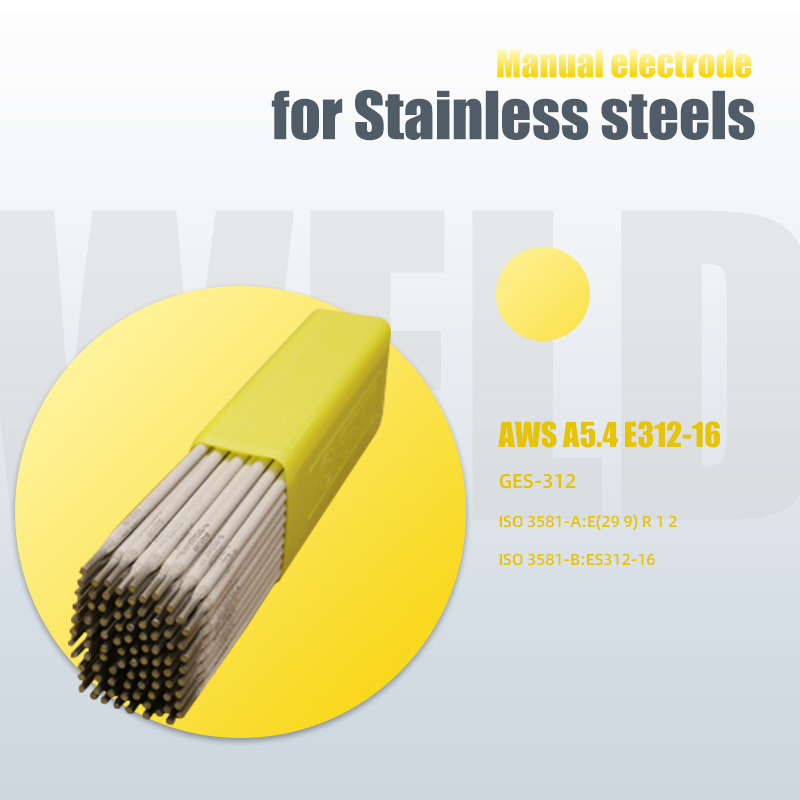

Super Purchasing for High Quality Spare Part Excavator Water Tank Radiator Part (E312)

GB/T983 E312-16

AWS A5.4 E312-16

ISO 3581-A:E(29 9) R 1 2

ISO 3581-B:ES312-16

Whatapp:+8613252436578

E-mail: sale@welding-honest.com

-

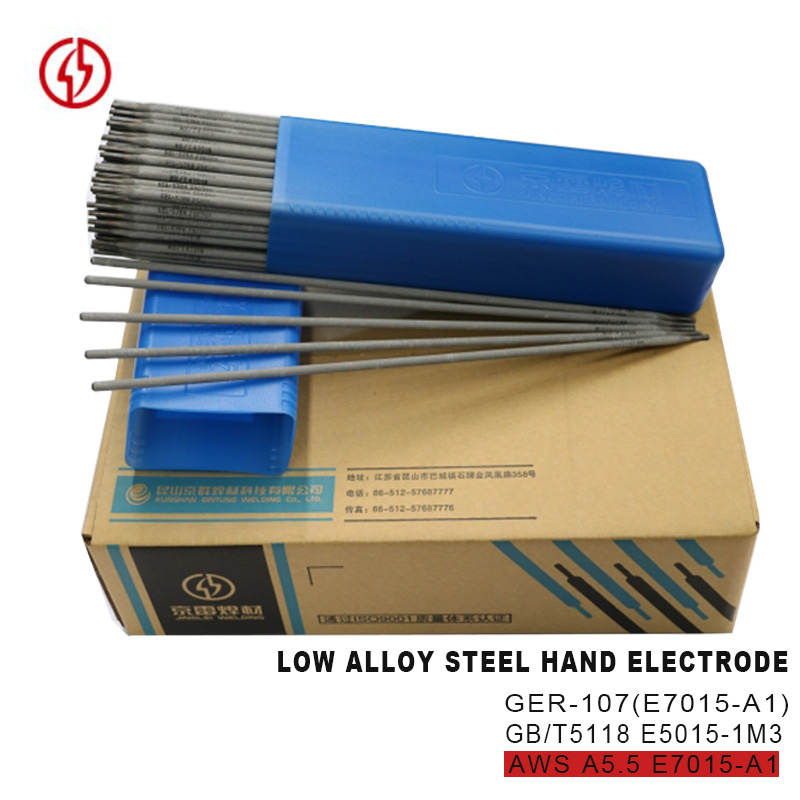

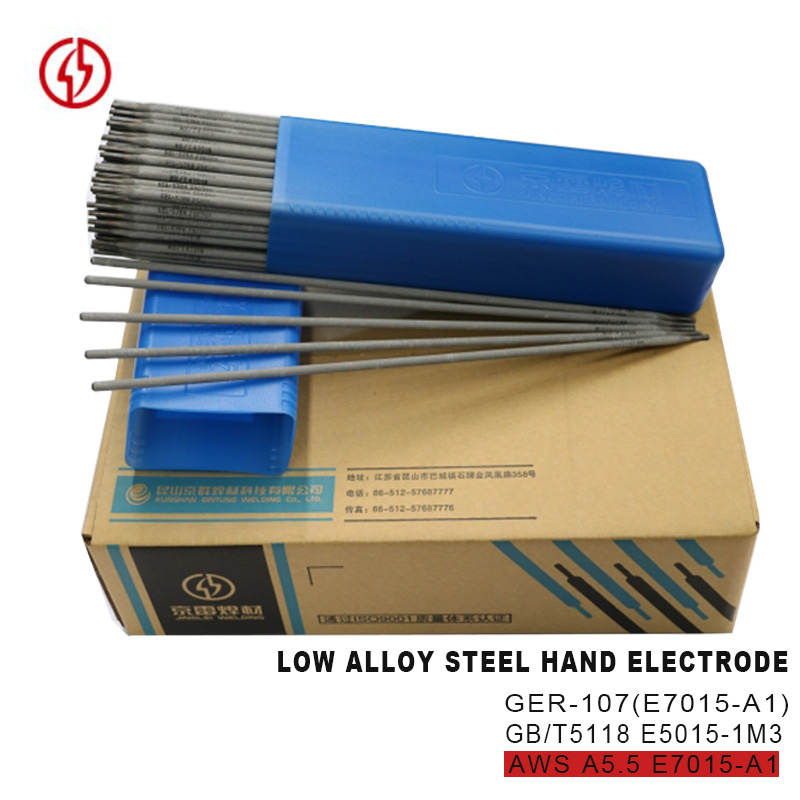

China Supplier E7015-G Low Hydrogen Sodium Coating Welding Electrodes

GER-107(R107) hand electrode for heat resisting steel,Jinglei R107 heat resistant steel electrode GB standard is E5015-1M3 P, suitable for welding working temperature in the following 510 degrees boiler pipe, heat exchanger and other occasions, such as ASTM A204 and A335-P1 pipe;

Welding items: 1. Preheating and channel (layer) temperature: 90-110℃; 2. Heat treatment: according to the standard requirements of welding materials, heat treatment is carried out at 620±15℃x1h.

-

Reasonable price Nickel-Iron Cast Iron Welding Electrodes Aws Eci Z208 Z308 Z408

GB/T10044 EZNi-1

AWS A5.15 ENi-Cl

ISO 1071:E C Ni-CL 3

-

Wholesale ODM TIG Welding Wire (SJ-50)

GB/T39280 W 49A 3 2

AWS A5.18 ER70S-2

A5.18M ER49S-2

ISO636-A:W 42 3 2Ti,

ISO636-B:W 49A 3 2

-

Good Quality OEM Service Brass wire for project

AWS E8015-B6 heat-resistant steel electrodes are used in 5%Cr-0.5%Mo steel electrodes, which are widely used in various welding scenarios in the market. We used in the process of electrode production source for the control of raw material suppliers, selected high-quality raw materials, coupled with our advanced production technology to carry on the processing of raw materials, with strict product inspection and good after-sales service, to provide our customers the highest quality products and best price of wire electrode.