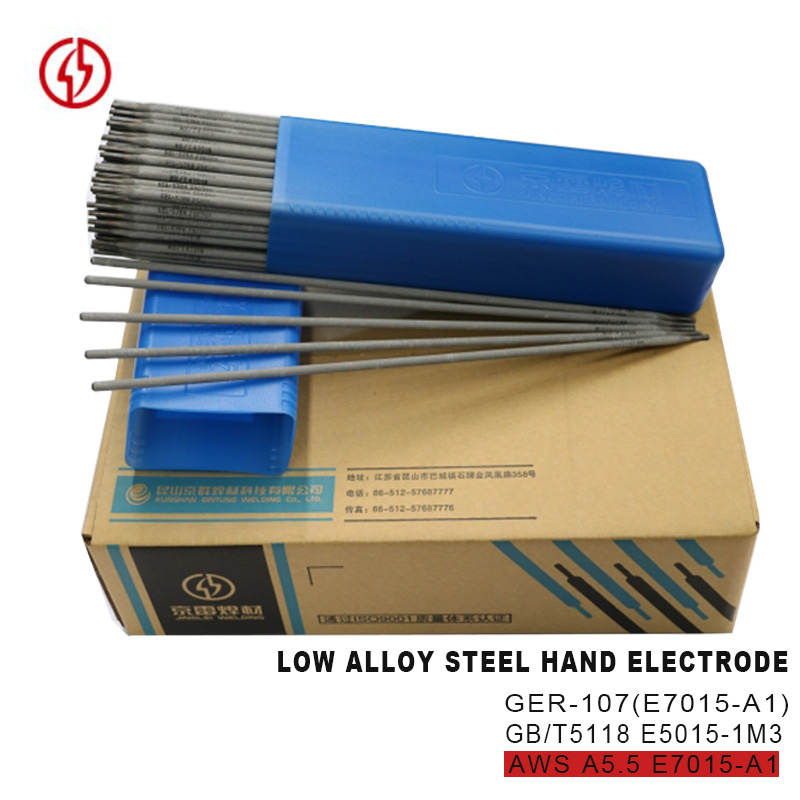

China Supplier E7015-G Low Hydrogen Sodium Coating Welding Electrodes

To meet the customers’ over-expected pleasure , we have now our solid crew to supply our greatest all round assistance which includes marketing, sales, planning, production, top quality controlling, packing, warehousing and logistics for China Supplier E7015-G Low Hydrogen Sodium Coating Welding Electrodes, We focus on creating own brand and in combination with many experienced term and first-class equipment . Our goods you worth have.

To meet the customers’ over-expected pleasure , we have now our solid crew to supply our greatest all round assistance which includes marketing, sales, planning, production, top quality controlling, packing, warehousing and logistics for China Welding Electrode and Welding Rod, With the aim of “compete with good quality and develop with creativity” and the service principle of “take customers’ demand as orientation”, we will earnestly provide qualified products and good service for domestic and international customers.

Application&Standard&Note:

E7015 type low alloy steel hand electrode is suitable for welding working temperature below 510℃ boiler pipe, heat exchanger and other occasions, such as ASTM A204 and A335-P1 pipe;

The electrode must be dried before use, keep a short arc, the use of backward forward welding method, avoid the occurrence of porosity at the arc; Low hydrogen should be maintained throughout the welding process. Low alloy steel electrode selection, usually according to the chemical composition of steel, mechanical properties, crack resistance and other requirements, but also from the welding structure shape, working conditions, stress and welding equipment and other aspects of comprehensive consideration. If necessary, welding performance tests shall be carried out to determine the electrode and necessary process measures shall be taken.

Features

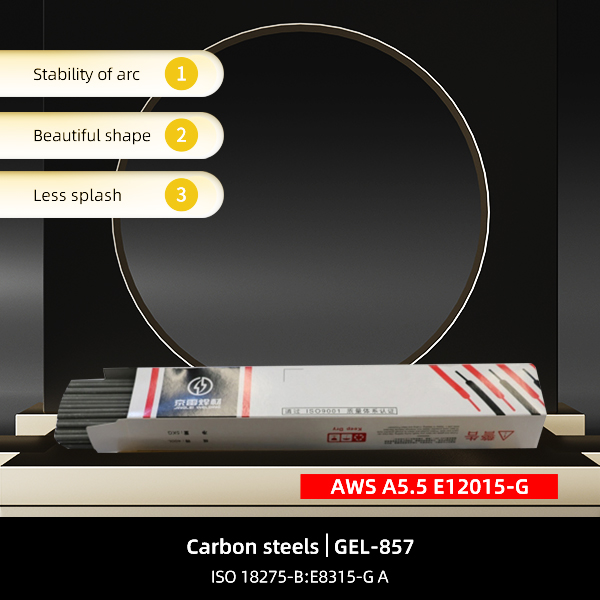

1. Low sodium hydrogen electrode, adding 0.5% Mo to improve weld strength and corrosion resistance;

2. Stable arc, less splash, good forming, easy to desagger, X-Ray performance is excellent.

Generally choose the corresponding electrode according to the strength of the steel grade, at the same time also need to steel weldability, the transition of parent metal components, dare to answer the structure size, shape, groove and the stress concentration factors, such as comprehensive consideration, the cooling speed of welding is too big, is a higher strength, weld street products easily crack the adverse circumstances, often can choose some less than the strength of parent metal electrode.

Company & Factory

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T RULES | 0.12 | 1.00 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| AWS RULES | 0.12 | 0.90 | 0.60 | - | 0.40-0.65 | 0.03 | 0.030 |

| EXAMPLE VALUE | 0.07 | 0.75 | 0.35 | 0.035 | 0.55 | 0.014 | 0.012 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||||||

| GB/T RULES | 390 | 490 | 620*1 | - | 22 | |||||||||

| AWS RULES | 390 | 490 | 620*1 | - | 22 | |||||||||

| EXAMPLE VALUE | 477 | 570 | 620*1 | 150/Normal temperature | 28 | |||||||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| ELECTRICITY (Amp) |

H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

PACKING DETAILES:

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||

Typical Cases

Certificate

To meet the customers’ over-expected pleasure , we have now our solid crew to supply our greatest all round assistance which includes marketing, sales, planning, production, top quality controlling, packing, warehousing and logistics for China Supplier E7015-G Low Hydrogen Sodium Coating Welding Electrodes, We focus on creating own brand and in combination with many experienced term and first-class equipment . Our goods you worth have.

China Supplier China Welding Electrode and Welding Rod, With the aim of “compete with good quality and develop with creativity” and the service principle of “take customers’ demand as orientation”, we will earnestly provide qualified products and good service for domestic and international customers.

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T RULES | 0.12 | 1.00 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| AWS RULES | 0.12 | 0.90 | 0.60 | - | 0.40-0.65 | 0.03 | 0.030 |

| EXAMPLE VALUE | 0.07 | 0.75 | 0.35 | 0.035 | 0.55 | 0.014 | 0.012 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||||||

| GB/T RULES | 390 | 490 | 620*1 | - | 22 | |||||||||

| AWS RULES | 390 | 490 | 620*1 | - | 22 | |||||||||

| EXAMPLE VALUE | 477 | 570 | 620*1 | 150/Normal temperature | 28 | |||||||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| ELECTRICITY (Amp) |

H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

PACKING DETAILES:

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||