AWS E7018-A1 Low-alloy steels Metal powder welding wire Welding accessories

Application&Standard&Note:

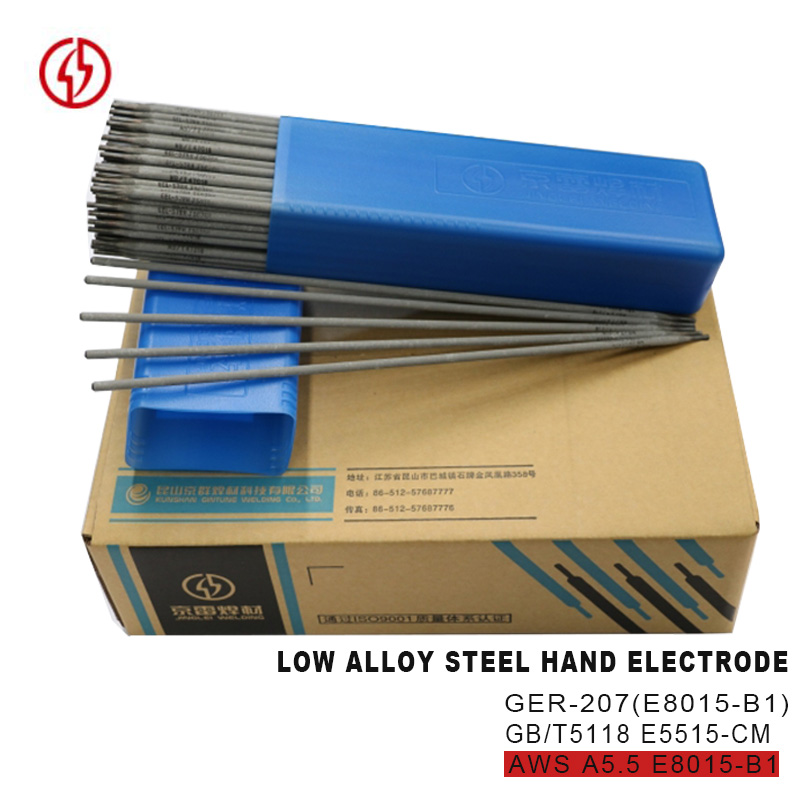

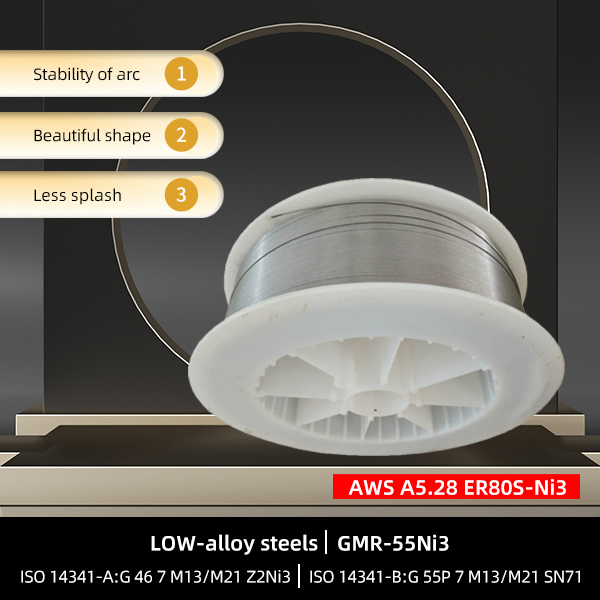

AWS E7018-A1 (R106Fe) heat-resistant steel hand electrode is suitable for welding boiler pipe, heat exchanger heating surface pipe and steam pipe below 450℃ (such as 15MoG, T1, P1 steel) and other occasions. Such as ASTM A204 and A335-P1 tubes; The weldment should be preheated to 90-110℃ before welding, and maintain the interlayer temperature. Can also be used for welding general low alloy steel high strength steel structure. And this hand electrode can be used for full position welding. According to the characteristics of the production process of low-temperature liquefied gas, the low-temperature steel is used in different grades according to different service temperatures (-40℃, -70℃, -100℃, -194℃, -253℃), and the corresponding welding materials are selected.

Features

This kind of hand electrode is iron powder low hydrogen type hand electrode, adding iron powder, high melting efficiency; 0.5% Mo is added to improve weld strength and corrosion resistance; And the arc is stable, less splashing, forming, desagging is easy, X-Ray performance is good.

The common alloying elements of pearlitic heat resistant steel are chromium, molybdenum, vanadium, niobium and so on to meet different working requirements. Due to the joint action of carbon alloy elements in steel, it is easy to form hardened structure during welding, and the welding performance is poor. Therefore, pearlitic heat-resistant steel is generally preheated before welding and tempered after welding.

Company & Factory

Product composition and mechanical properties introduction

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T RULES | 0.12 | 1.00 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| AWS RULES | 0.12 | 0.90 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| EXAMPLE VALUE | 0.6 | 0.7 | 0.31 | 0.035 | 0.5 | 0.012 | 0.01 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||||||

| GB/T RULES | 390 | 490 | 620*1 | - | 22 | |||||||||

| AWS RULES | 390 | 490 | 620*1 | - | 22 | |||||||||

| EXAMPLE VALUE | 480 | 570 | 620*1 | 170/Normal temperature | 26 | |||||||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| ELECTRICITY (Amp) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

PACKING DETAILES:

| SEPCIFICATION | LENGTH | PCS/1KG | WEIGHT/1KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||

Typical Cases

Certificate

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T RULES | 0.12 | 1.00 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| AWS RULES | 0.12 | 0.90 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| EXAMPLE VALUE | 0.6 | 0.7 | 0.31 | 0.035 | 0.5 | 0.012 | 0.01 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||||||

| GB/T RULES | 390 | 490 | 620*1 | - | 22 | |||||||||

| AWS RULES | 390 | 490 | 620*1 | - | 22 | |||||||||

| EXAMPLE VALUE | 480 | 570 | 620*1 | 170/Normal temperature | 26 | |||||||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| ELECTRICITY (Amp) |

H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

PACKING DETAILES:

| SEPCIFICATION | LENGTH | PCS/1KG | WEIGHT/1KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||