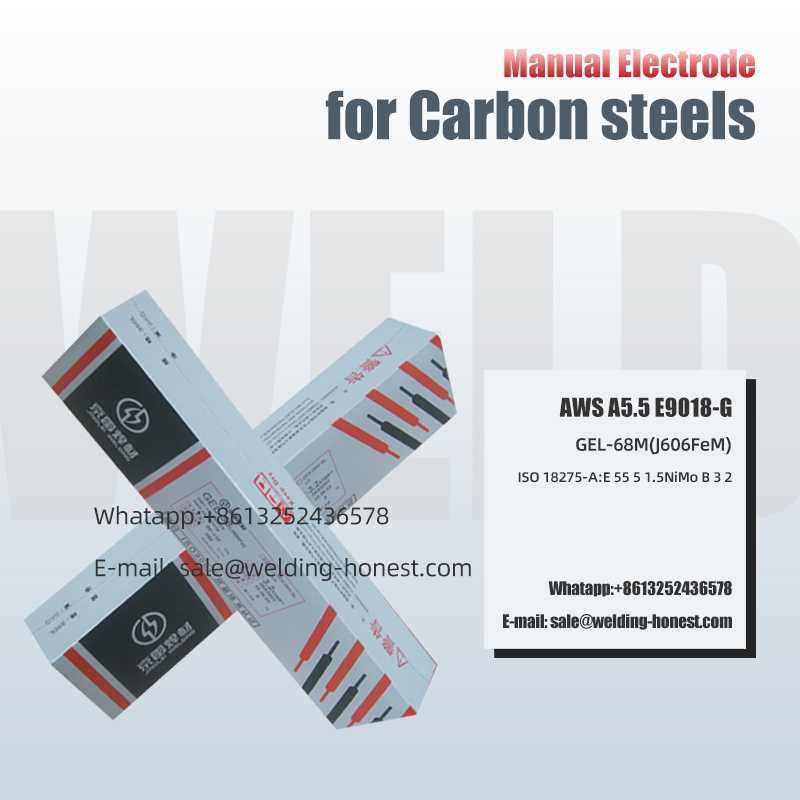

High Carbon steels ER80S-G Solid wire welding stuff

Application & Standard

1. Suitable for steel structure, bridge, construction machinery, pressure vessels and other welding occasions, high current mainly used for flat welding, flat fillet welding.

2. The standard we met: GB/T8110 G 55A 4 C1/M21 S12 , AWS A5.28 ER80S-G & A5.28M ER55S-G, ISO14341-A, ISO 14341-B:G 55A 4 C1/M21 S16 JIS Z3313 T49T1-1CA-U

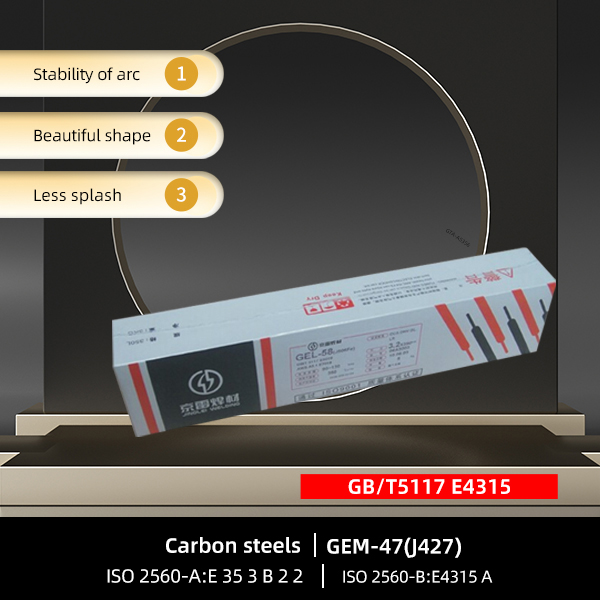

Features

1. It has a wide range of current application and stable arc characteristics.

2. The wire feeding is smooth, the arc is stable, the forming is beautiful, the molten iron fluidity is good, the splash is less, has the excellent welding welding process performance.

3. The molten metal has good mechanical properties.

Company & Factory

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | Ti |

| GB/T RULES | 0.02-0.15 | 1.25-1.90 | 0.55-1.00 | - | - | - | 0.030 | 0.030 | 0.50 | - |

| AWS RULES | - | - | - | ≥0.30· | ≥0.50 | ≥0.20 | - | - | - | - |

| EXAMPLE VALUE | 0.075 | 1.600 | 0.70 | 0.08 | 0.05 | 0.4 | 0.007 | 0.004 | 0.210 | 0.11 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||

| GB/T RULES | 460 | 550-740 | AW | 27/-40 | 17 | |||||

| AWS RULES | - | 550 | - | - | - | |||||

| EXAMPLE VALUE | 570 | 650 | AW | 122/-20 75/-40 | 23 | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1 | 1.2 | 1.6 | |

| AMP | H/W | 80-250 | 100-350 | 250-300 |

| O/W | 70-120 | 80-150 | - | |

TYPICAL CASES

Certificates

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | Ti |

| GB/T RULES | 0.02-0.15 | 1.25-1.90 | 0.55-1.00 | - | - | - | 0.030 | 0.030 | 0.50 | - |

| AWS RULES | - | - | - | ≥0.30· | ≥0.50 | ≥0.20 | - | - | - | - |

| EXAMPLE VALUE | 0.075 | 1.600 | 0.70 | 0.08 | 0.05 | 0.4 | 0.007 | 0.004 | 0.210 | 0.11 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||

| GB/T RULES | 460 | 550-740 | AW | 27/-40 | 17 | |||||

| AWS RULES | - | 550 | - | - | - | |||||

| EXAMPLE VALUE | 570 | 650 | AW | 122/-20 75/-40 | 23 | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1 | 1.2 | 1.6 | |

| AMP | H/W | 80-250 | 100-350 | 250-300 |

| O/W | 70-120 | 80-150 | - | |