ISO 3581-A Stainless steels Manual electrode Welding accessories

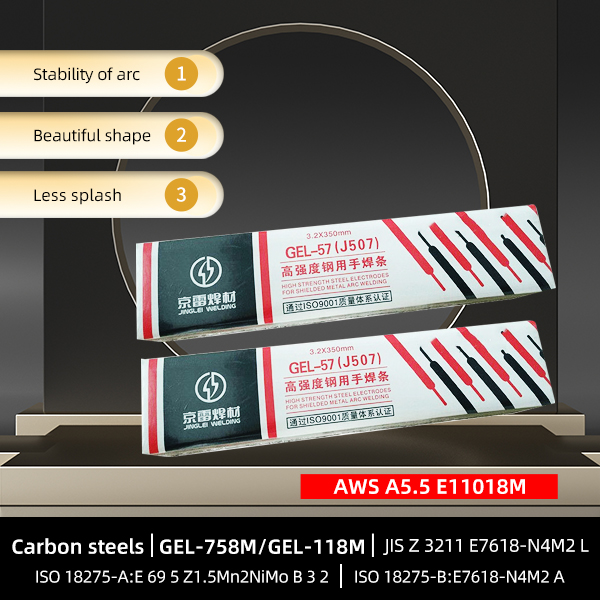

Application&Standard&Note:

1. Suitable FOR WELDING OF CARBON STEEL AND LOW ALLOY STEEL, AS WELL AS THE CORRESPONDING STRENGTH OF BOILER, pipeline, vehicle, BUILDING, BRIDGE AND other STRUCTURES, SUCH AS Q345.

2. The standard we met: GB/T5117 E5016, AWS A5.1 E7016 & A5.1M E4916, ISO2560-A:E 42 3 B 1 2, ISO 2560-B: E4916 A

Welding precautions:

Before welding, the weldment must be entirely free of oil, rust, moisture, etc.; drying at 350°C for an hour; and drying with use

3. Use narrow pass welding and short arc welding; AC and DC reverse connections.

Can be used for welding low carbon steel and 490MPa high strength steel pipe butt joint, can realize single-side welding double-side forming.

The electrode belongs to the low hydrogen type, welding pipe and the general structure of the root of the weld, can realize single-sided welding two-sided forming, so it can save the cleaning welding heel, so that the welding efficiency can be improved.

Key points of process:

1, drying before use, 300~350℃ drying 30~60 minutes;

2, choose the appropriate current and groove, in order to get a beautiful back weld;

3. When extinguishing the arc, lead the arc pit to the side of the groove and then break the arc;

4. Arc starting time using arc starting plate or on the side of the groove arc;

5. Keep short arc welding;

6. Use AC or DC reverse connection.

Features

1. Titanium calcium stainless steel electrode, the main composition is 18% CR-8% Ni-6%Mn;

2. Stable arc, beautiful forming, fine ripples, few splashes, easy de-slagging, good fire resistance of drug skin, good stomatal resistance.

3. Stable mechanical properties, X-ray pass rate is high.

E307-16with Grade (AWS A5.4),Stainless steel welding Electrode is a different kind of welding steel such as welding austenitic manganese to carbon steel castings or forgings.

They are extensively used in diverse applications industry and are formed from urbane technology and the superior grade of raw materials with newest characteristics, These SS welding electrodes can also be custom-made relating to their size and thickness as per clients requirements.

Company & Factory

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.20 | 4.5-7.5 | 1.20 | 17-20 | 44752.00 | 0.75 | 0.035 | 0.03 | 0.75 |

| AWS RULES | - | - | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.071 | 5.58 | 1.03 | 19.12 | 8.9 | 0.2 | 0.028 | 0.006 | 0.012 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||||||

| GB/T RULES | 350 | 500 | - | - | 25 | |||||||||

| AWS RULES | - | - | - | - | - | |||||||||

| EXAMPLE VALUE | - | 635 | - | - | 36 | |||||||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||||

| ELECTRICITY (Amp) |

H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||||

PACKING DETAILES:

| SEPCIFICATION | LENGTH | PCS/1KG | WEIGHT/1KG | |||

| 2.0mm | 300mm | 79PCS | 2KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||

NOTE:

H/W: horizontal position welding

O/W: over-head position welding

Typical Cases

Certificate

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.20 | 4.5-7.5 | 1.20 | 17-20 | 44752.00 | 0.75 | 0.035 | 0.03 | 0.75 |

| AWS RULES | - | - | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.071 | 5.58 | 1.03 | 19.12 | 8.9 | 0.2 | 0.028 | 0.006 | 0.012 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||||||

| GB/T RULES | 350 | 500 | - | - | 25 | |||||||||

| AWS RULES | - | - | - | - | - | |||||||||

| EXAMPLE VALUE | - | 635 | - | - | 36 | |||||||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||||

| ELECTRICITY (Amp) |

H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||||

PACKING DETAILES:

| SEPCIFICATION | LENGTH | PCS/1KG | WEIGHT/1KG | |||

| 2.0mm | 300mm | 79PCS | 2KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||

NOTE:

H/W: horizontal position welding

O/W: over-head position welding