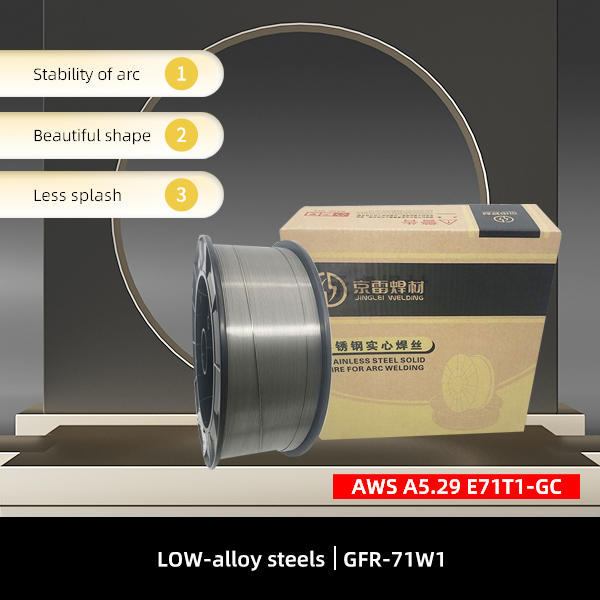

Low-alloy steels Flux cored wire E71T1-GC weld fabrication jointing

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.12 | 0.80-1.60 | 0.20-0.80 | 0.10-0.40 | 0.30-0.80 | - | 0.03 | 0.03 | 0.20-0.50 |

| AWS RULES | - | ≥0.50 | 1.00 | ≥0.30 | ≥0.50 | ≥0.50 | 0.03 | 0.03 | - |

| EXAMPLE VALUE | 0.03 | 1.2 | 0.34 | 0.48 | 0.48 | 0.26 | 0.011 | 0.006 | 0.35 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Heat treatment°Cxh | |||||

| GB/T RULES | 390 | 490-670 | 27/-40 | 18 | AW | |||||

| AWS RULES | 400 | 490-620 | - | 20 | AW | |||||

| EXAMPLE VALUE | 510 | 575 | 95/-40 | 26 | AW | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.2 | 1.4 | 1.6 | |||||||

| Volt | 25-32 | 24-36 | 25-40 | |||||||

| Amp | 150-300 | 170-360 | 200-400 | |||||||

| Dry extension length(mm) | 15-20 | 15-20 | 18-25 | |||||||

| Gas flow(l/min) | 15-25 | 15-25 | 15-25 | |||||||

The arc is soft and stable, less splash, beautiful forming, good slag removal.

Less soot, with excellent welding process performance.

Fused metal contains Cu, Ni, Cr, so its atmospheric corrosion resistance is good, excellent cracking resistance.

Tianshu Xing, a large liquefied natural gas (LNG) carrier with 174,000 cubic meters, was built as a bow

-

YAMAL LNG project

-

Sino-russian Eastern Front

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.12 | 0.80-1.60 | 0.20-0.80 | 0.10-0.40 | 0.30-0.80 | - | 0.03 | 0.03 | 0.20-0.50 |

| AWS RULES | - | ≥0.50 | 1.00 | ≥0.30 | ≥0.50 | ≥0.50 | 0.03 | 0.03 | - |

| EXAMPLE VALUE | 0.03 | 1.2 | 0.34 | 0.48 | 0.48 | 0.26 | 0.011 | 0.006 | 0.35 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Heat treatment°Cxh | |||||

| GB/T RULES | 390 | 490-670 | 27/-40 | 18 | AW | |||||

| AWS RULES | 400 | 490-620 | - | 20 | AW | |||||

| EXAMPLE VALUE | 510 | 575 | 95/-40 | 26 | AW | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.2 | 1.4 | 1.6 | |||||||

| Volt | 25-32 | 24-36 | 25-40 | |||||||

| Amp | 150-300 | 170-360 | 200-400 | |||||||

| Dry extension length(mm) | 15-20 | 15-20 | 18-25 | |||||||

| Gas flow(l/min) | 15-25 | 15-25 | 15-25 | |||||||

Write your message here and send it to us