Low-alloy steels Flux cored wire E81T1-B2C Welding accessories

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S |

| GB/T RULES | 0.05-0.12 | 1.25 | 0.80 | 1.00-1.50 | - | 0.40-0.65 | 0.03 | 0.03 |

| AWS RULES | 0.05-0.12 | 1.25 | 0.80 | 1.00-1.50 | - | 0.40-0.65 | 0.03 | 0.03 |

| EXAMPLE VALUE | 0.055 | 0.83 | 0.25 | 1.09 | 0.01 | 0.45 | 0.01 | 0.005 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Heat treatment°Cxh | |||||

| GB/T RULES | 470 | 550-690 | - | 17 | 690*1 | |||||

| AWS RULES | 470 | 550-690 | - | 19 | 690*1 | |||||

| EXAMPLE VALUE | 545 | 625 | 72/Normal temperature | 23 | 690*1 | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.2 | ||||

| Volt | 24-35 | ||||

| Amp | 160-320 | ||||

| Dry extension length(mm) | 15-20 | ||||

| Gas flow(l/min) | 15-25 | ||||

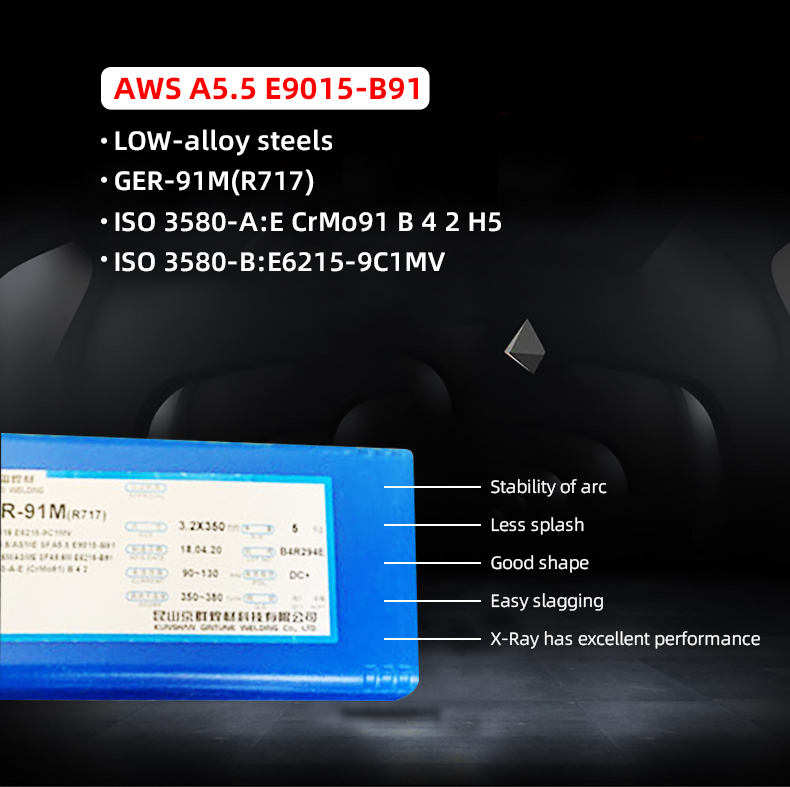

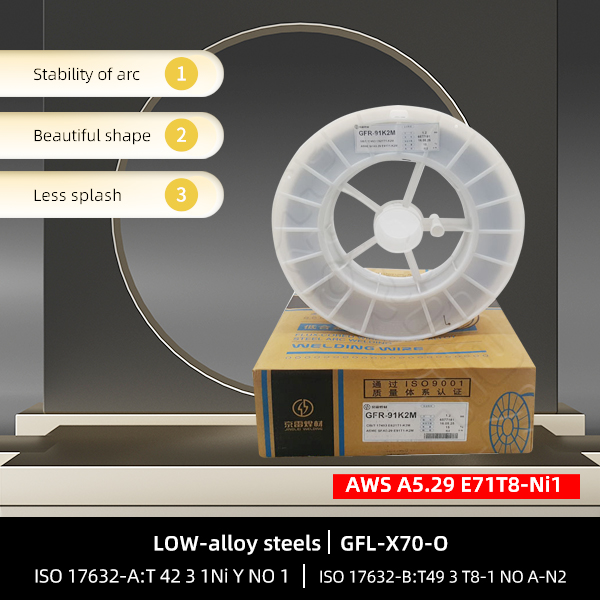

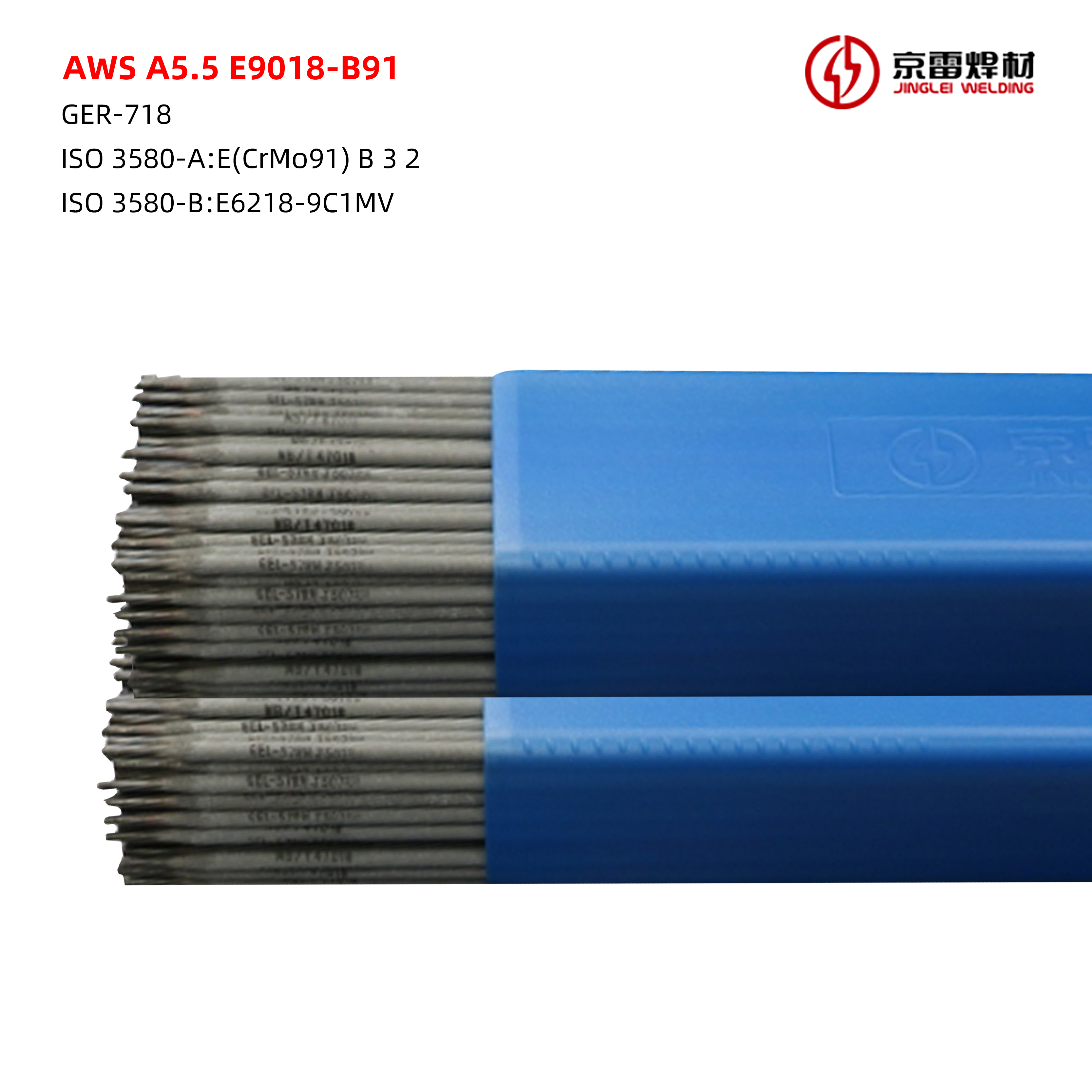

The arc is soft and stable, less splash.

Beautiful forming, good slag removal.

Less soot, with excellent welding process performance.

-

The 174,000 cubic meter liquefied natural gas (LNG) ship Nongnongbok Seok

-

JU2000E jack-up drilling platform

-

China A heavy hydrogenation reactor

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S |

| GB/T RULES | 0.05-0.12 | 1.25 | 0.80 | 1.00-1.50 | - | 0.40-0.65 | 0.03 | 0.03 |

| AWS RULES | 0.05-0.12 | 1.25 | 0.80 | 1.00-1.50 | - | 0.40-0.65 | 0.03 | 0.03 |

| EXAMPLE VALUE | 0.055 | 0.83 | 0.25 | 1.09 | 0.01 | 0.45 | 0.01 | 0.005 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Heat treatment°Cxh | |||||

| GB/T RULES | 470 | 550-690 | - | 17 | 690*1 | |||||

| AWS RULES | 470 | 550-690 | - | 19 | 690*1 | |||||

| EXAMPLE VALUE | 545 | 625 | 72/Normal temperature | 23 | 690*1 | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.2 | ||||

| Volt | 24-35 | ||||

| Amp | 160-320 | ||||

| Dry extension length(mm) | 15-20 | ||||

| Gas flow(l/min) | 15-25 | ||||

Write your message here and send it to us