Low-Alloy Steels Manual Electrode E9018-B92 large liquefied gas carrier weld

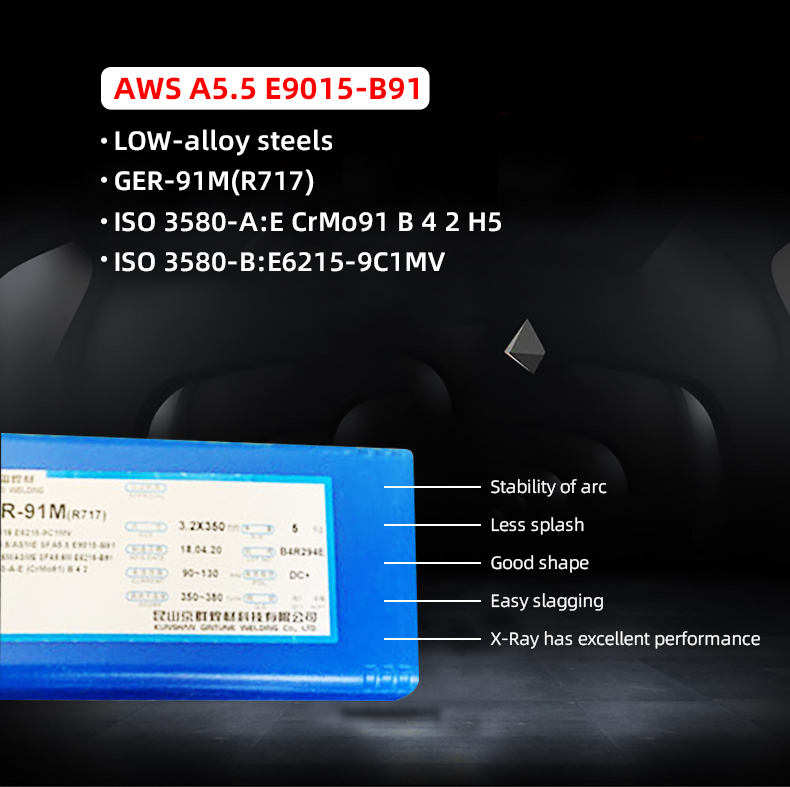

Due to the addition of a small amount of Nb, V, at 600C high temperature can have excellent creep resistance of iron powder low hydrogen system coating

Core wire transition alloy

AC and DC dual use, can be welded in all positions

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Si | Mn | P | S | Ni | Cr | Mo | Other | |

| GB/T RULES | 0.092 | 0.21 | 0.62 | 0.006 | 0.004 | 0.55 | 9.21 | 0.51 | V:0.2 Nb:0.05 W:1.64 N:0.035 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | Elongation(%) | IMAPACT VALUE J/℃ | Heat treatment °C*h | |||||

| GB/T RULES | 634 | 730 | 21 | 58/Normal temperature | 760*2 | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY (Amp) |

H/W | 70-120 | 90-130 | 140-190 | 170-220 | ||||

| O/W | 60-100 | 80-120 | 120-160 | - | |||||

-

Zhejiang Satellite Energy 3× 60,000 m³LPG storage tank

-

Mei Jin Hua Sheng

glycol synthetic tower

-

Carbon steel,

stainless steel tower welding

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Si | Mn | P | S | Ni | Cr | Mo | Other | |

| GB/T RULES | 0.092 | 0.21 | 0.62 | 0.006 | 0.004 | 0.55 | 9.21 | 0.51 | V:0.2 Nb:0.05 W:1.64 N:0.035 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | Elongation(%) | IMAPACT VALUE J/℃ | Heat treatment °C*h | |||||

| GB/T RULES | 634 | 730 | 21 | 58/Normal temperature | 760*2 | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | |||||

| ELECTRICITY (Amp) |

H/W | 70-120 | 90-130 | 140-190 | 170-220 | ||||

| O/W | 60-100 | 80-120 | 120-160 | - | |||||

Write your message here and send it to us