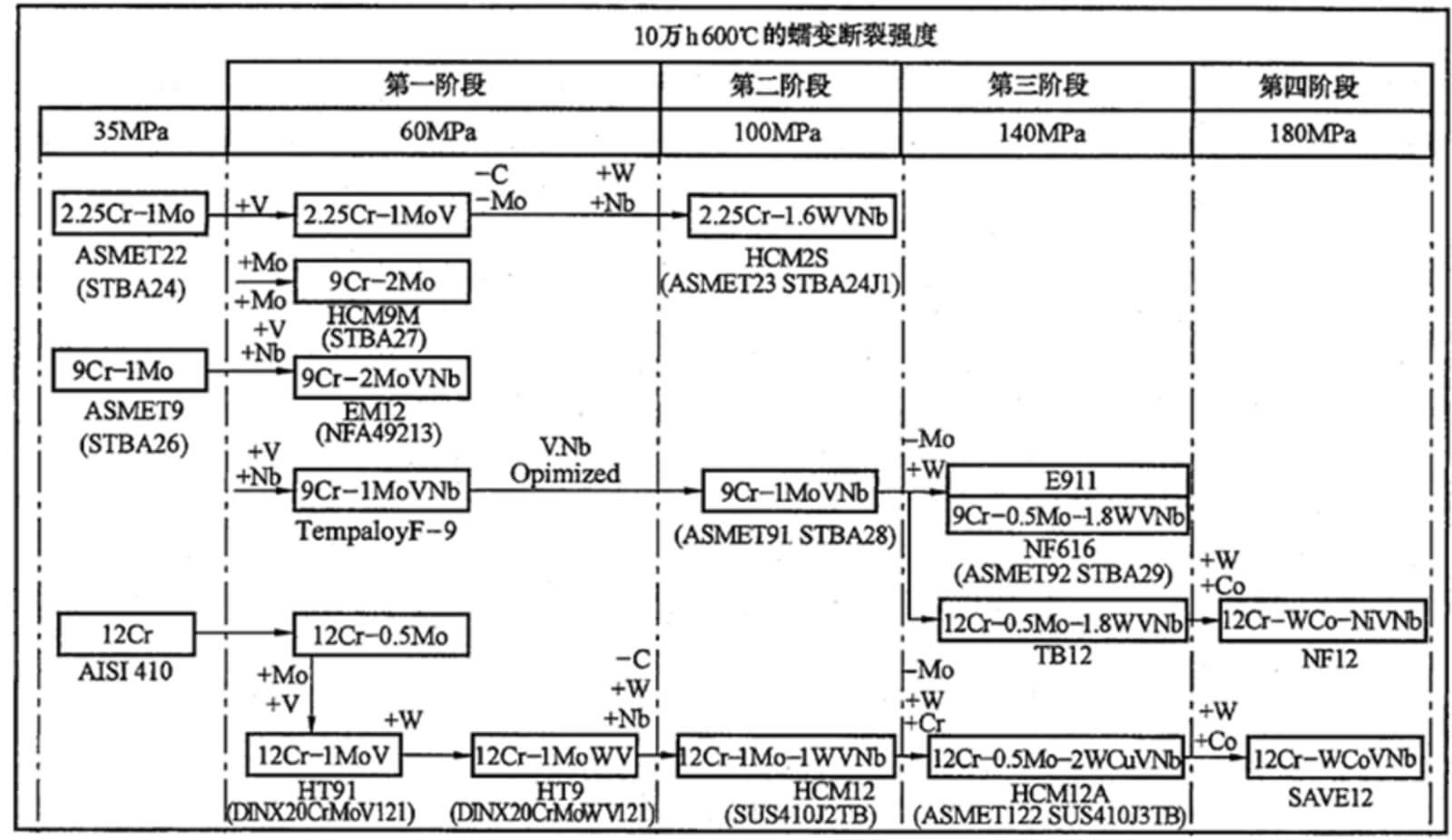

Development of ferritic heat-resistant steel

Increase Cr-1.25Cr to 12Cr

Add V, Nb, Mo, W, Co, etc.

Development trend of ferritic heat-resistant steel

Note:

According to international practice, the so-called pearlite, bainite, and martensitic heat-resistant steels in boiler and pipeline steels are collectively referred to as “ferritic heat-resistant steels”.

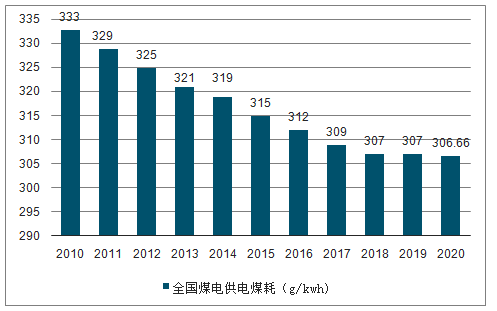

With the adjustment of my country’s energy structure and the optimization of power supply construction, high-efficiency, clean, and environmentally friendly large-capacity and high-parameter units have become dominant. By increasing the steam parameters (pressure and temperature), it can effectively improve the thermal efficiency of the unit, reduce coal consumption, and reduce CO2 emissions. At present, the main way to improve the efficiency of thermal power units is to improve steam parameters and develop supercritical (SC) and ultra-supercritical (USC) units. At present, there are more than 100 million-kilowatt ultra-supercritical (USC) units put into operation in my country, ranking first in the world in both quantity and total capacity.

Statistics and Forecast of Coal Consumption of Coal Power Supply in China from 2010 to 2020

2.Main Chromium Molybdenum Steel Welding Rod Products

Table 2 Performance display of representative pearlitic heat-resistant steel electrodes

|

Item |

Main ingredient |

Heat℃*H |

Mechanical behavior |

||||

|

Yield Mpa |

Tensile Mpa |

Extend % |

Shock J/℃ |

||||

|

GER-107 |

0.5%Mo |

620*1 |

477 |

570 |

24.0 |

152/0 |

- |

|

GER-207 |

0.5%Cr-0.5%Mo |

690*1 |

490 |

590 |

23.0 |

143/0 |

- |

|

GER-307 |

1.25%Cr-0.5%Mo |

690*1 |

490 |

590 |

23.0 |

146/0 |

- |

|

GER-317 |

1.25%Cr-0.5%Mo-V |

730*2 |

541 |

635 |

22.5 |

166/0 |

- |

|

GER-407 |

2.25%Cr-1%Mo |

690*1 |

586 |

682 |

21.0 |

142/0 |

- |

|

GER-417 |

2.25%Cr-1%Mo-V |

720*8 |

556 |

657 |

21.0 |

145/-18 |

120/-30 |

|

GER-507 |

5%Cr-0.5%Mo |

740*1 |

490 |

605 |

23.0 |

124/0 |

- |

Note:

1. Our company has developed EXXXX-15, EXXXX-16, EXXXX-18 and other coating slag series for electrodes of the same grade to meet different market demands. The above only shows the performance of EXXXX-15 electrodes.

3.2 List of subcritical and super (ultra) critical ferritic/martensitic heat-resistant steel electrodes

|

ITEM |

STANDARD |

Main Charcter |

|

GER-707 |

AWS A5.5 E8015-B8 GB/T 5118 E6215-9C1M |

9%Cr-1%Mo Carbon steel core wire, the main alloy composition is transitioned from the coating, suitable for thermal power subcritical units, A213-T9, A335-P9 steel welding (economical and applicable, good workmanship) |

|

GER-91 Core type |

AWS A5.5 E9015-B91 GB/T 5118 E6215-9C1MV |

9%Cr-1%Mo-Nb-v-n Suitable for thermal power critical units, T/P 91 steel welding, the main alloy composition is transferred from the welding core, high temperature microstructure and performance stability |

|

GER-91M drug skin core |

9%Cr-1%Mo-Nb-V-N Suitable for thermal power critical units, T/P 91 steel welding, the main alloy composition is transferred from the welding core, high temperature microstructure and performance stability | |

|

GER-92 Core type |

AWS A5.5 E9015-B92 |

9%Cr-0.5%Mo-W-V-Nb-N Suitable for thermal power supercritical units, T/P 92 steel welding, the main alloy composition is transitioned from the core wire, high temperature microstructure and performance stability |

|

GER-93 |

Our standard |

9%Cr-3%W-3%Co-Cu-V-Nb-B It is suitable for the welding of advanced high supercritical G115 steel for thermal power generation. It has good structure and performance stability at high temperature. The durable strength is 1.5 times that of P92 steel, and its resistance to high temperature steam oxidation and corrosion is better than that of P92 steel. |

Electrode performance display

|

Item |

Main ingredient |

Heat℃*H |

Mechanical behavior |

|||

|

Yield Mpa |

Tensile Mpa |

Extend % |

Shock J |

|||

|

GER-707 |

9%Cr-1%Mo |

740*1 |

540 |

670 |

24.0 |

119.7 |

|

GER-91 |

9%Cr-1%Mo-Nb-V-N |

760*2 |

557 |

702 |

21.0 |

96.3 |

|

GER-91M |

9%Cr-1%Mo-Nb-V-N |

760*2 |

553 |

701 |

22.5 |

81.0 |

|

GER-92 |

9%Cr-0.5%Mo-W-V-Nb-N |

760*2 |

596 |

706 |

21.5 |

103.0 |

|

GER-93 |

9%Cr-3%W-3%Co |

770*4 |

580 |

720 |

20.0 |

77.7 |

Note:

1. GER-91M is coating transition, that is, the welding core is ordinary carbon steel core wire, and the main alloy is transitioned by coating. Compared with GER-91 (core wire transition type), it has better economic benefits and is our super The main products of welding rods for supercritical thermal power.

3.The 2015 version of ASME standard requires E9015-B91 electrode Mn+Ni≤1.4%, and the 2017 version requires ≤1.2% for the base metal. (2021 latest version of ASME continues to use the 2015 version of ASME’s composition requirements for E9015-B91/ B92 electrodes). In order to meet the market demand, our E9015-B91 and E9015-B92 welding rods have developed two types of corresponding welding materials: Mn+Ni≤1.4% and Mn+Ni≤1.2%. Because the latter has more market demand, the above shows 91/ 92 electrodes are deposited metal Mn+Ni≤1.2%.

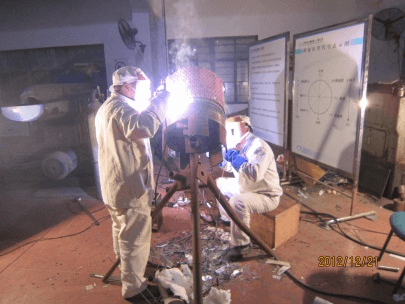

4. Demonstration of process evaluation for ultra-supercritical electrodes

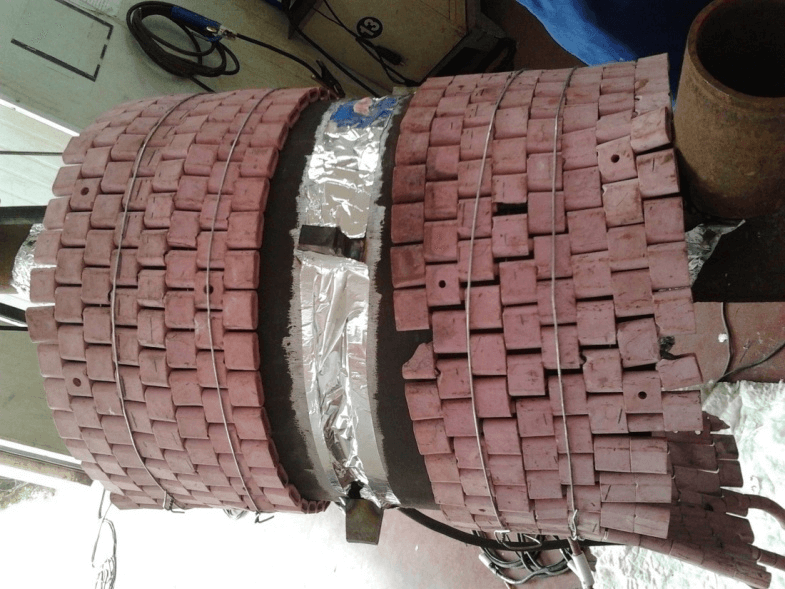

4.1 Process qualification of P91/92 welded joints

6. Advantages and characteristics of our heat-resistant steel electrodes for chrome-molybdenum steel

1. There are many varieties and all kinds

●The composition ranges from 0.5%Mo to 9%Cr-3%W-3%Co.

●Use temperature from 500℃ to 650℃.

●Different coating colors and coating types (EXXXX-15, EXXXX-16, EXXXX-18) can be applied to different occasions (general type, strong arc force type for power construction pipelines).

●It can meet the welding requirements of most Cr-Mo steels.

2. Good performance

Excellent mechanical properties, good high temperature performance (high temperature creep and high temperature aging properties).

3. Good craftsmanship

The electrode has excellent manufacturability in all positions, stable arc combustion, good stiffness and blowing force, small spatter, good fluidity, beautiful weld shape, and easy slag removal after welding.

4. Industry leading

Cooperated with Suzhou Institute of Thermal Engineering, and passed the review of “T/P 91/92 Localization Appraisal Meeting” in 2015, and cooperated with major domestic power units such as Shenhua Guohua and General Iron and Steel Research Institute to develop 650°C G115 steel supporting welding materials and processes , and held several welding consumables exchange meetings.

More information send to E-mail: export@welding-honest.com

Post time: Dec-27-2022