In duplex stainless steel (DSS), the austenite phase and the ferrite phase account for about half of the solid solution structure, and have two-phase structure characteristics. It not only retains the characteristics of ferritic stainless steel, such as large thermal conductivity, small linear expansion coefficient, resistance to pitting corrosion and crevice corrosion, and chloride stress corrosion, but also has good toughness, low brittle transition temperature and resistance to intergranular corrosion of austenitic stainless steel. With good performance and other advantages, it is widely used in petrochemical, printing and dyeing, marine engineering, food industry and paper making industries.

With the trend of increasing the size of modern industrial equipment and reducing production costs, some large components are mostly manufactured by overlaying duplex stainless steel corrosion-resistant layers on low-alloy steel substrates.

Strip electroslag surfacing process is widely used in manufacturing because of its stable welding quality, high degree of automation, and high production efficiency.

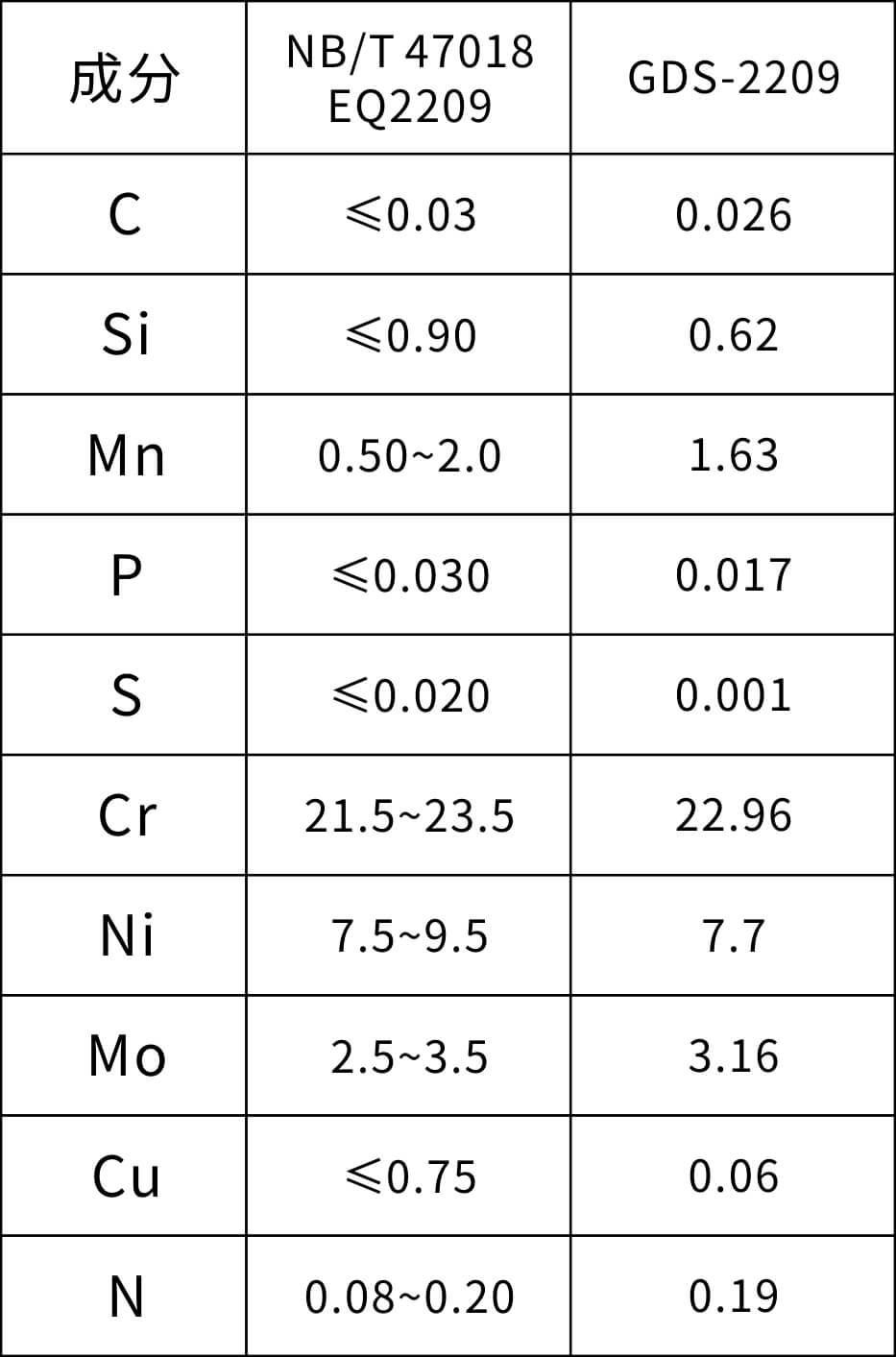

Table 1 GDS-2209 ribbon composition

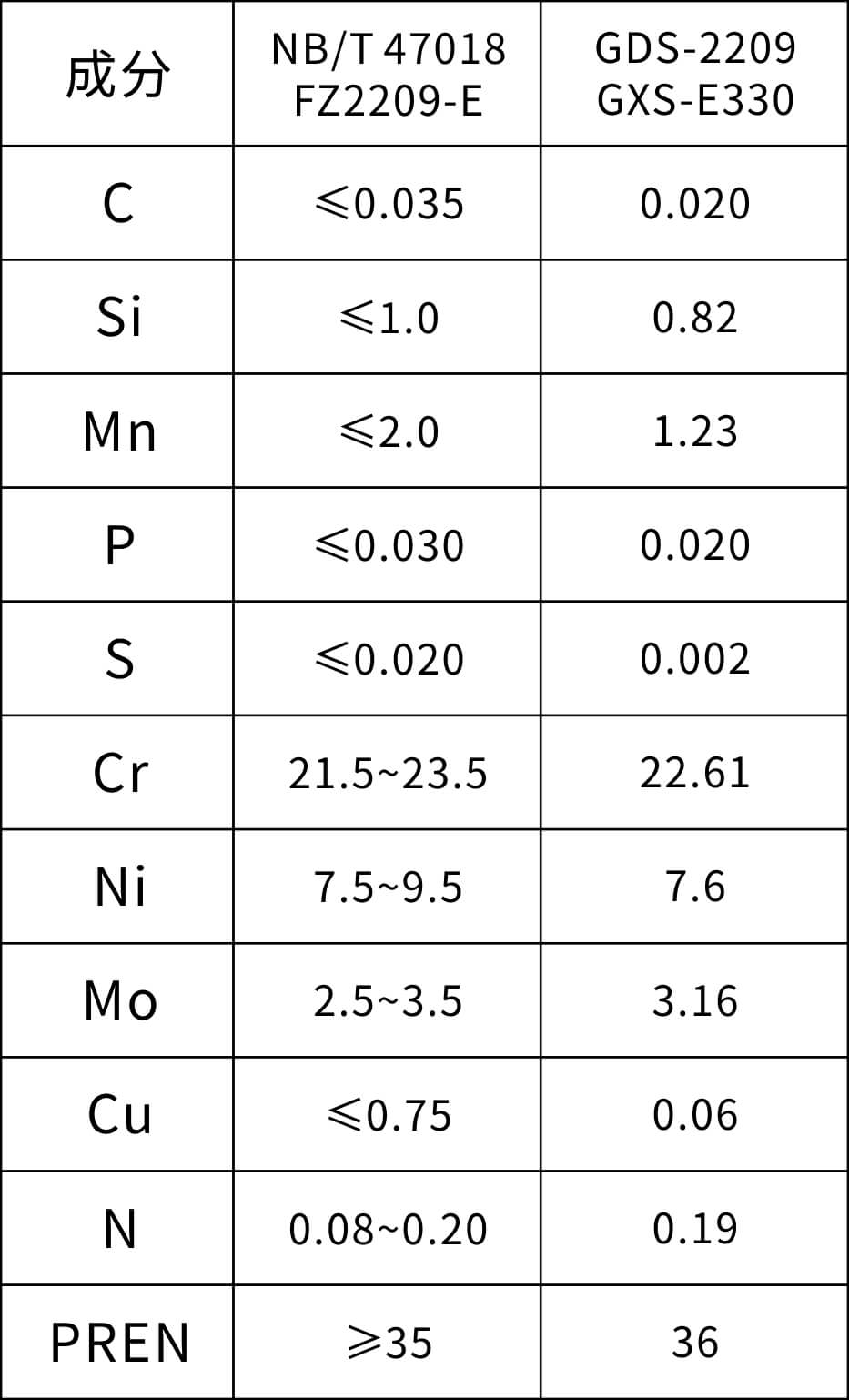

Table 2 GDS-2209&GXS-E330 deposited metal composition

Table 3 GDS-2209&GXS-E330 bending and corrosion resistance test

|

Test items |

Elbow diameter 4T 180 lateral side bend |

GB/T 4334E intergranular corrosion |

ASTM A923 C (22℃*24H) |

Measured ferrite |

|

Require |

Surfacing layer ≤ 1.5mm opening defect |

No intergranular corrosion cracks |

≤10 mdd |

35-65% |

|

Test results |

No opening defect |

no crack |

1.9mdd |

38.3 |

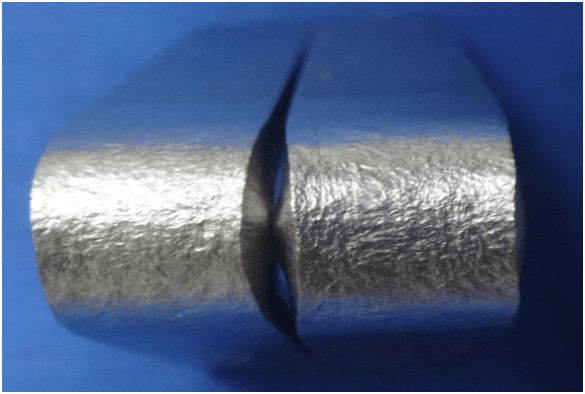

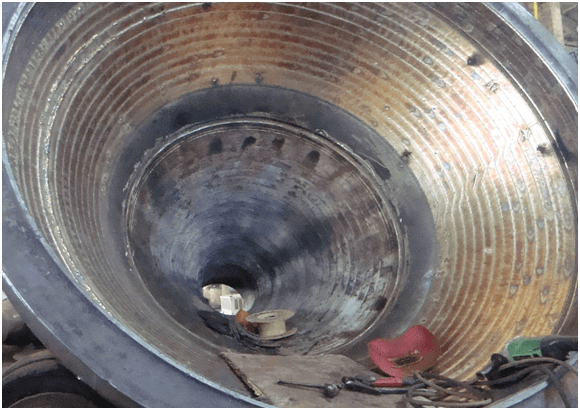

GDS-2209&GXS-E330 welding bead pictures

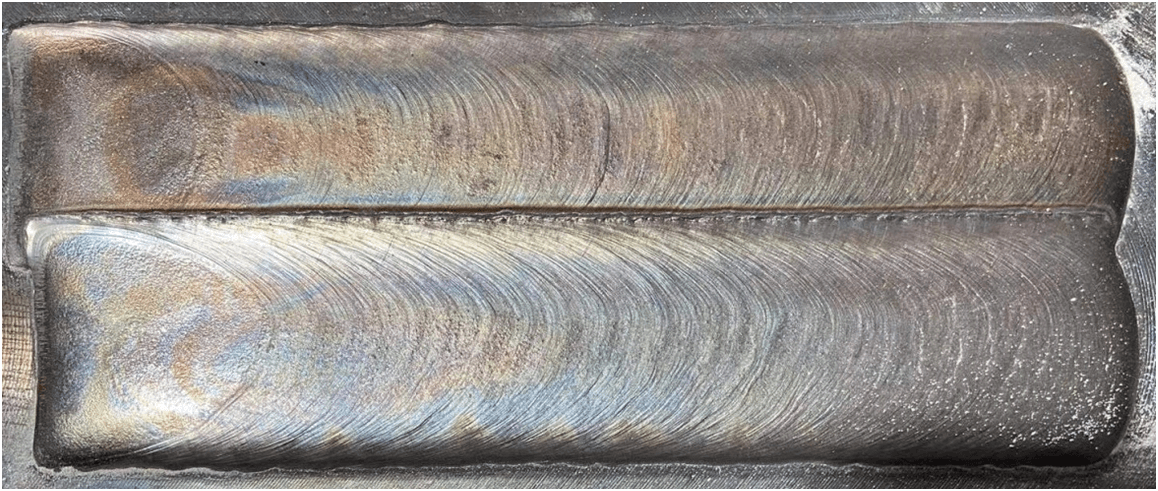

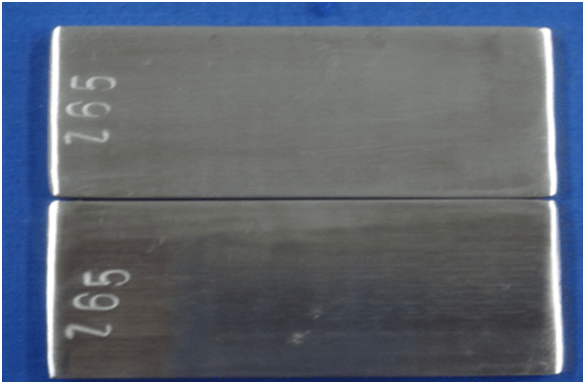

GB/T 4334.E method intergranular corrosion pictures

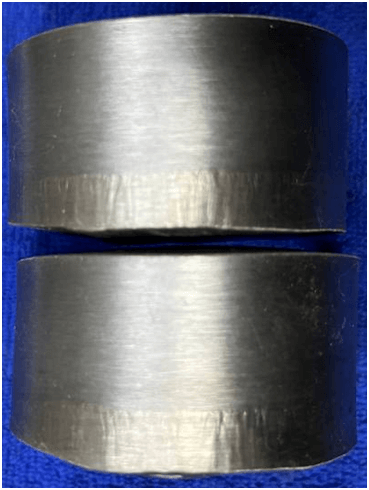

ASTM A923C Intergranular Corrosion Picture 4T180 lateral side bending picture

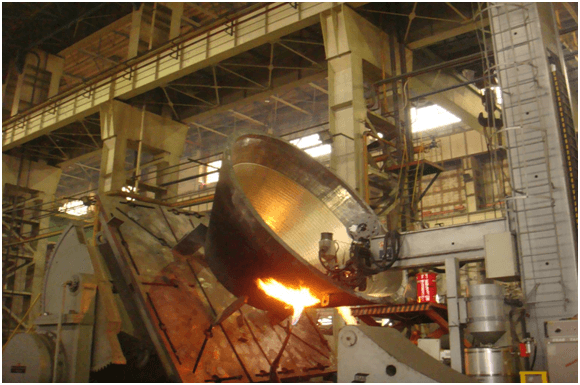

Field application of strip surfacing welding

The duplex stainless steel strip surfacing products developed by our company (strip GDS-2209 with GXS-E330 flux) have excellent welding workability and physical and chemical properties, which can meet the needs of production and manufacturing. Welcome to inquire and purchase.

Post time: Dec-17-2022