Nickel alloys Manual electrode ENiCrFe-7 Welding connection

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Fe | Nb | Cu | Mo | |

| GB/T RULES | 0.05 | 5.00 | 0.80 | 28.0-31.5 | ≥50 | 7.0-12.0 | 1.0-2.5 | 0.50 | 0.50 | |

| AWS RULES | 0.05 | 5.00 | 0.75 | 28.0-31.5 | Margin | 7.0-12.0 | 1.0-2.5 | 0.50 | 0.50 | |

| EXAMPLE VALUE | 0.048 | 2.5 | 0.33 | 29.6 | 56.9 | 9 | 1.45 | 0.017 | 0.050 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 360 | 550 | - | 27 | ||||

| AWS RULES | - | 550 | - | 30 | ||||

| EXAMPLE VALUE | 450 | 650 | - | 41.5 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | ||||||||

| ELECTRICITY (Amp) |

H/W | 69-95 | 70-115 | 95-145 | |||||||

| O/W | 55-80 | 65-110 | 80-130 | ||||||||

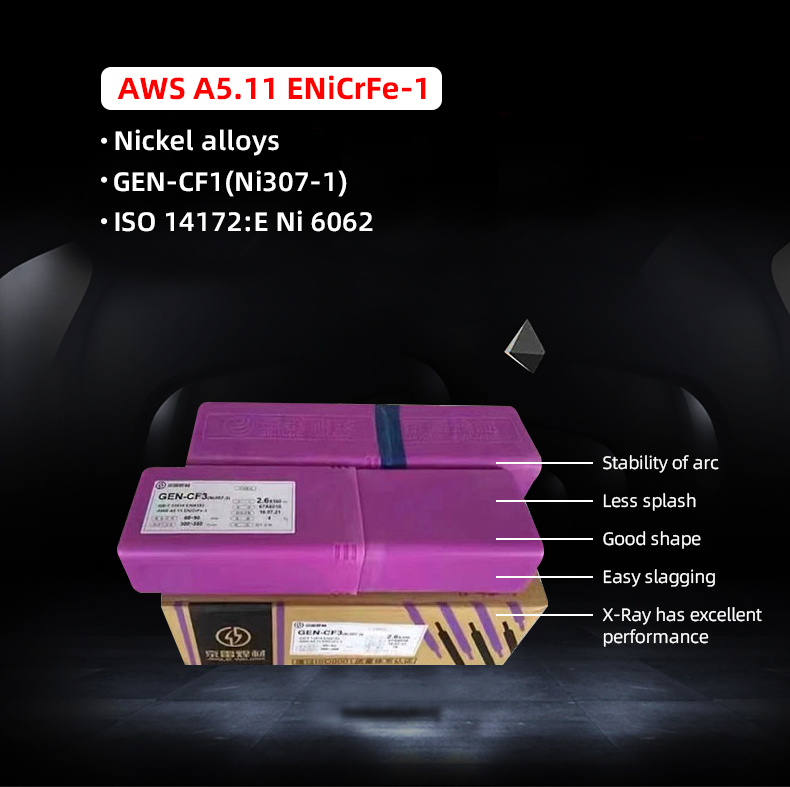

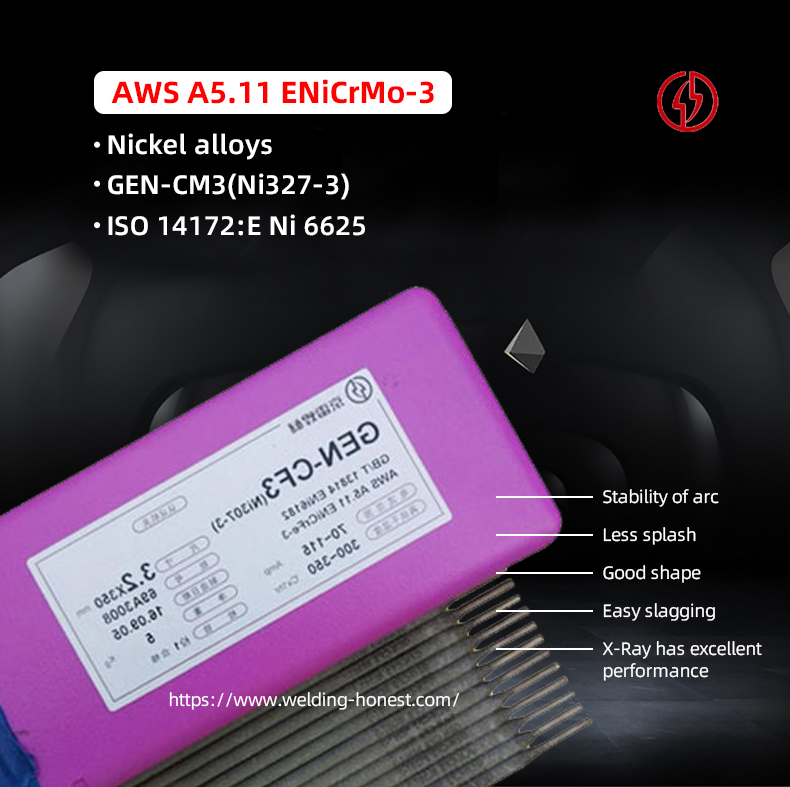

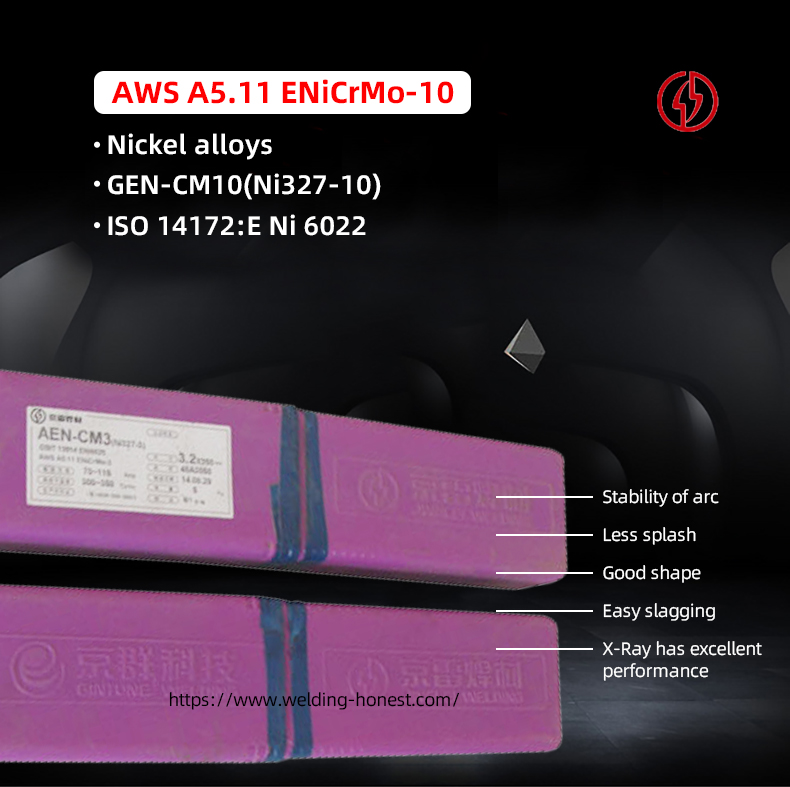

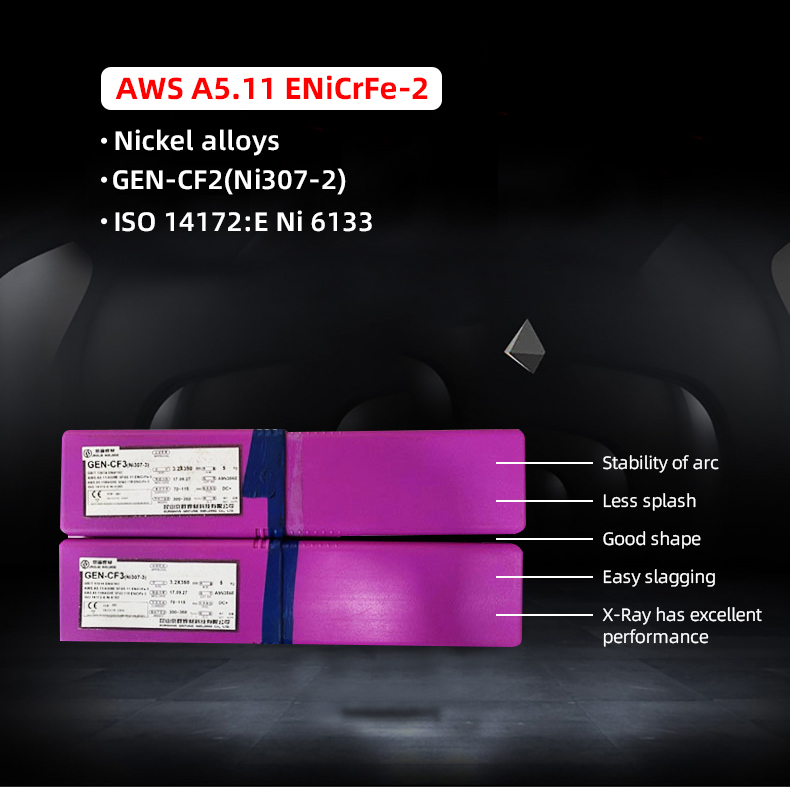

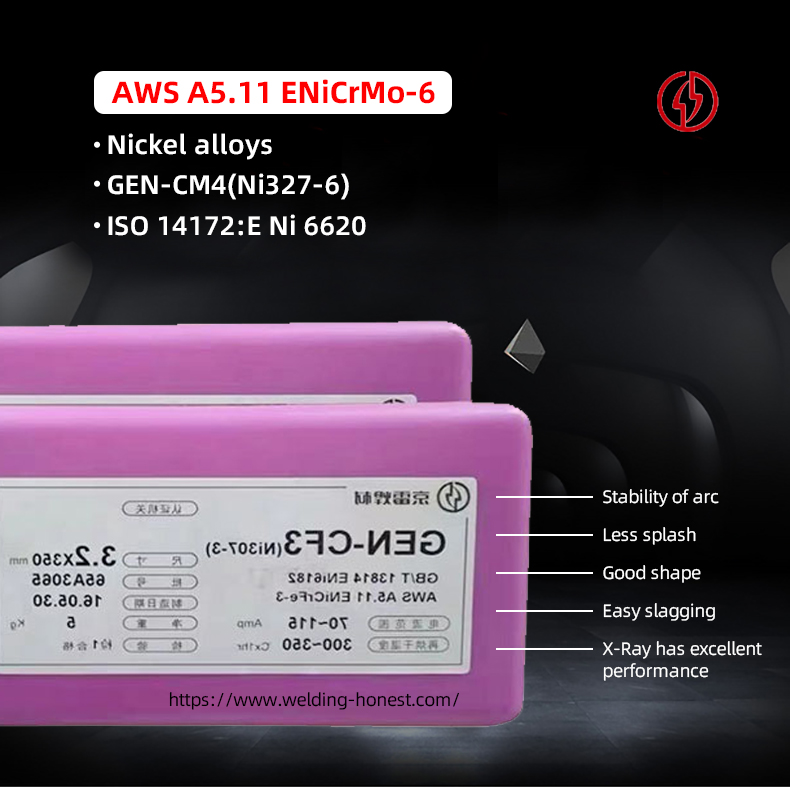

Low hydrogen type hand electrode, nominal composition (weight percent) is 55Ni-29Cr-9.5Fe-3Mn-1.5Nb+Ta, nickel - chromium - iron alloy electrode.

High Cr content makes it have better resistance to stress corrosion cracking in nuclear radiation and pure water environment.

Stable arc, beautiful forming, little splash, easy slagging, good porosity resistance, stable mechanical properties of molten metal, and good corrosion resistance in high temperature oxidation and sulfur-containing atmosphere.

-

Sinopec refining and Chemical Project

-

Hainan Huasheng phenol recovery tower

-

Carbon steel, stainless steel tower welding

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Fe | Nb | Cu | Mo | |

| GB/T RULES | 0.05 | 5.00 | 0.80 | 28.0-31.5 | ≥50 | 7.0-12.0 | 1.0-2.5 | 0.50 | 0.50 | |

| AWS RULES | 0.05 | 5.00 | 0.75 | 28.0-31.5 | Margin | 7.0-12.0 | 1.0-2.5 | 0.50 | 0.50 | |

| EXAMPLE VALUE | 0.048 | 2.5 | 0.33 | 29.6 | 56.9 | 9 | 1.45 | 0.017 | 0.050 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 360 | 550 | - | 27 | ||||

| AWS RULES | - | 550 | - | 30 | ||||

| EXAMPLE VALUE | 450 | 650 | - | 41.5 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.6*300 | 3.2*350 | 4.0*350 | ||||||||

| ELECTRICITY (Amp) |

H/W | 69-95 | 70-115 | 95-145 | |||||||

| O/W | 55-80 | 65-110 | 80-130 | ||||||||