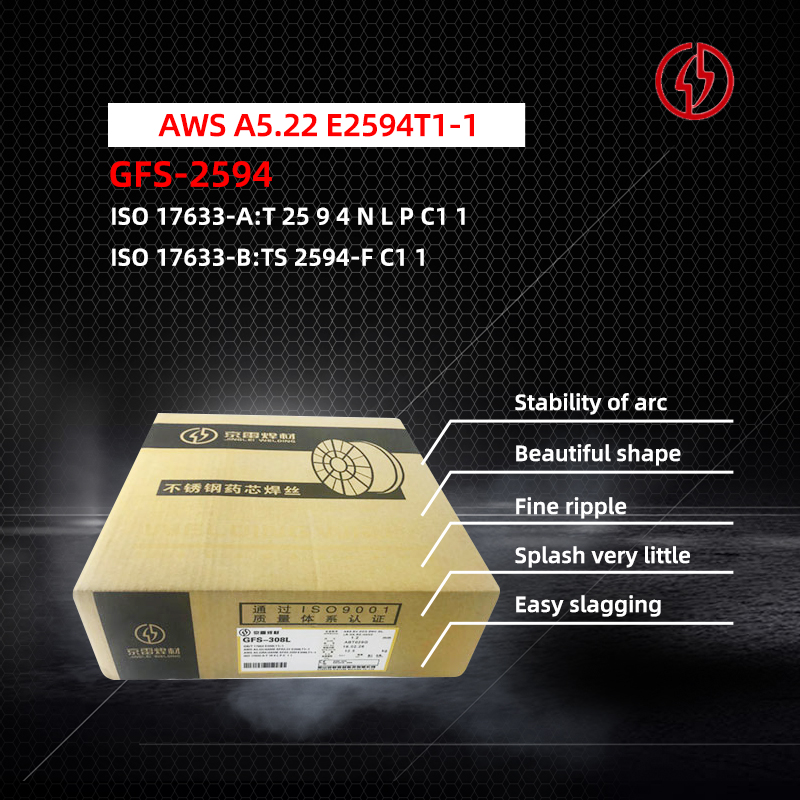

Stainless steels Flux cored wire E2594T1-1 metal Jointing stuff

Application

Applicable to the welding of 25%Cr duplex steels such as super duplex stainless steel UNS S32750 and UNS J93380.

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | N | Cu | W | |

| GB/T RULES | 0.04 | 0.5-2.5 | 1.00 | 24.0-27.0 | 8.0-10.5 | 2.5-4.5 | 0.04 | 0.03 | 0.2-0.3 | 1.50 | 1.00 | |

| AWS RULES | 0.04 | 0.5-2.5 | 1.00 | 24.0-27.0 | 8.0-10.5 | 2.5-4.5 | 0.04 | 0.03 | 0.2-0.3 | 1.50 | 1.00 | |

| EXAMPLE VALUE | 0.025 | 1.15 | 0.65 | 24.8 | 9 | 3.5 | 0.018 | 0.002 | 0.23 | 0.02 | 0.01 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | - | 760 | - | 13 | ||||

| AWS RULES | - | 760 | - | 15 | ||||

| EXAMPLE VALUE | - | 883 | - | 25 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.2 | 1.6 | ||||||

| Volt | 22-36 | 26-38 | ||||||

| Amp | 120-260 | 200-300 | ||||||

| Dry extension length(mm) | 15-20 | 18-25 | ||||||

| Gas flow(l/min) | 15-25 | 15-25 | ||||||

Peculiarity

The weld microstructure is austenitic ferrite biphase structure.

Excellent pitting resistance, PREN(pitting resistance equivalent)≥40.

The arc is soft and stable, less splash, beautiful forming, good slag removal, stable wire feeding, with excellent welding process performance.

Show details

Beautiful shape

Good slag removal

About us

Factory fioor display

Application case

Welding materials for containers

China Science & Technology Co., LTD. 20 million tons/year refining and chemical integration project

Actual factory shooting

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | N | Cu | W | |

| GB/T RULES | 0.04 | 0.5-2.5 | 1.00 | 24.0-27.0 | 8.0-10.5 | 2.5-4.5 | 0.04 | 0.03 | 0.2-0.3 | 1.50 | 1.00 | |

| AWS RULES | 0.04 | 0.5-2.5 | 1.00 | 24.0-27.0 | 8.0-10.5 | 2.5-4.5 | 0.04 | 0.03 | 0.2-0.3 | 1.50 | 1.00 | |

| EXAMPLE VALUE | 0.025 | 1.15 | 0.65 | 24.8 | 9 | 3.5 | 0.018 | 0.002 | 0.23 | 0.02 | 0.01 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | - | 760 | - | 13 | ||||

| AWS RULES | - | 760 | - | 15 | ||||

| EXAMPLE VALUE | - | 883 | - | 25 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.2 | 1.6 | ||||||

| Volt | 22-36 | 26-38 | ||||||

| Amp | 120-260 | 200-300 | ||||||

| Dry extension length(mm) | 15-20 | 18-25 | ||||||

| Gas flow(l/min) | 15-25 | 15-25 | ||||||

Write your message here and send it to us