Stainless steels Flux cored wire E410NiMot1-1 Soldering connection

Application

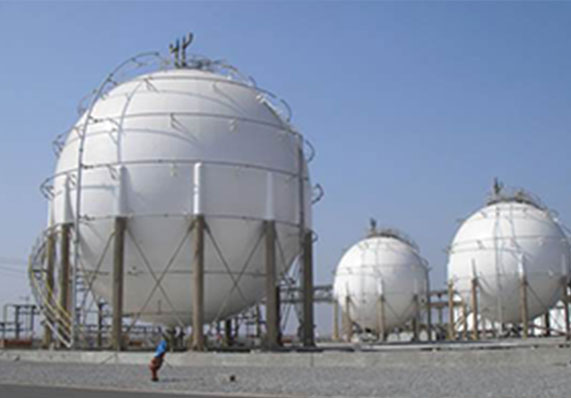

Suitable for demanding water turbine rotor, valve and other wear and corrosion resistance occasions.

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | |

| GB/T RULES | 0.06 | 1.00 | 1.00 | 11.0-12.5 | 4.0-5.0 | 0.4-0.7 | 0.04 | 0.03 | 0.75 | |

| AWS RULES | 0.06 | 1.00 | 1.00 | 11.0-12.5 | 4.0-5.0 | 0.4-0.7 | 0.04 | 0.03 | 0.75 | |

| EXAMPLE VALUE | 0.03 | 0.27 | 0.33 | 11.35 | 11.35 | 0.49 | 0.015 | 0.005 | 0.01 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | - | 760 | - | 10 | ||||

| AWS RULES | - | 760 | - | 15 | ||||

| EXAMPLE VALUE | - | 885 | - | 17 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.2 | 1.6 | ||||||

| Volt | 22-36 | 26-38 | ||||||

| Amp | 150-300 | 200-350 | ||||||

| Dry extension length(mm) | 15-20 | 18-25 | ||||||

| Gas flow(l/min) | 15-25 | 15-25 | ||||||

Peculiarity

Due to the addition of alloy components Ni and Mo, the corrosion resistance is more stable.

The hardness and high temperature wear resistance are improved, and the generation of cold and hot cracks is effectively prevented.

The arc is soft and stable, less splash, beautiful forming, good slag removal, stable wire feeding, with excellent welding process performance.

Show details

Soft and stable

Less splash

About us

Factory fioor display

Application case

Arctic LNG-2 project

Shaanxi Pucheng -50℃ propane spherical tank project

Actual factory shooting

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | |

| GB/T RULES | 0.06 | 1.00 | 1.00 | 11.0-12.5 | 4.0-5.0 | 0.4-0.7 | 0.04 | 0.03 | 0.75 | |

| AWS RULES | 0.06 | 1.00 | 1.00 | 11.0-12.5 | 4.0-5.0 | 0.4-0.7 | 0.04 | 0.03 | 0.75 | |

| EXAMPLE VALUE | 0.03 | 0.27 | 0.33 | 11.35 | 11.35 | 0.49 | 0.015 | 0.005 | 0.01 | |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | - | 760 | - | 10 | ||||

| AWS RULES | - | 760 | - | 15 | ||||

| EXAMPLE VALUE | - | 885 | - | 17 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.2 | 1.6 | ||||||

| Volt | 22-36 | 26-38 | ||||||

| Amp | 150-300 | 200-350 | ||||||

| Dry extension length(mm) | 15-20 | 18-25 | ||||||

| Gas flow(l/min) | 15-25 | 15-25 | ||||||

Write your message here and send it to us