Hard-facing Manual electrode weld fabrication accessories

Application & Standard

GEH-547Mo is a hand electrode corresponding to GB/T984 ED CrNi-B-15, which is applied to all kinds of surfacing welding and metal surface welding. It is mainly used for surfacing of high-pressure valve sealing surface with working temperature lower than 600℃. By surfacing specific alloy on the surface of the substrate, it can meet the needs of wear resistance and corrosion resistance. High temperature resistance or a combination of working conditions. Whether reducing production costs, improving product utilization through multiple repairs, or facilitating control of the construction and shape of the workpiece, are the most convenient and economical methods. The so-called hard surface wear technology is commonly referred to as metal surface surfacing, spraying or repair.

Features

GEH-547Mo is a low sodium hydrogen coated high chromium nickel valve surfacing electrode, using DC reverse connection. The surfacing metal is strengthened by Si, Mo, W, V, Nb and other elements to obtain the autonitic structure with a small amount of ferrite, which has good high temperature abrasion resistance and erosion resistance, high temperature hardness, good thermal stability and thermal fatigue resistance. The aging hardening effect of metal surfacing is remarkable. With the aging time increasing, the hardness and abrasion resistance are further improved. It is suitable for surfacing the sealing surface of high pressure valve with working temperature below 600℃, all kinds of valve shell, valve seat, gate plate, main valve head, safety door core and valve disc, etc.

Company & Factory

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Nb | P | S |

| GB/T RULES | 0.18 | 0.60-5.00 | 3.80-6.50 | 14.00-21.00 | 6.50-12.00 | 3.50-7.00 | 0.50-1.20 | 0.04 | 0.03 |

| AWS RULES | - | - | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.05 | 1.26 | 5.34 | 16.1 | 8.1 | 3.8 | 0.61 | 0.028 | 0.007 |

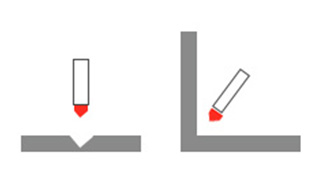

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) |

80-120 | 120-160 | 160-210 | |||||

TYPICAL CASES

Certificates

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Nb | P | S |

| GB/T RULES | 0.18 | 0.60-5.00 | 3.80-6.50 | 14.00-21.00 | 6.50-12.00 | 3.50-7.00 | 0.50-1.20 | 0.04 | 0.03 |

| AWS RULES | - | - | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.05 | 1.26 | 5.34 | 16.1 | 8.1 | 3.8 | 0.61 | 0.028 | 0.007 |

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) |

80-120 | 120-160 | 160-210 | |||||