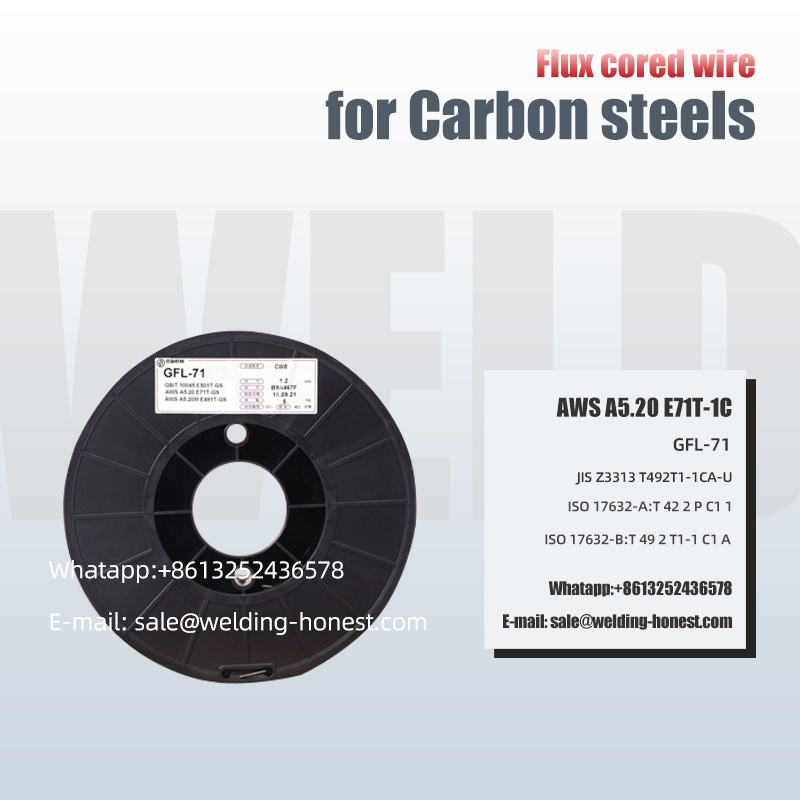

High Carbon steels E71T-1C Flux cored wire welding stuff

Application & Standard

1. Suitable for ship, bridge, construction, offshore platform, pipeline, steel structure welding.

2. The standard we met: GB/T10045 T 49 2 T1-1 C1 A , AWS A5.20 E71T-1C & A5.20M E491T-1C, ISO17632-A:T42 2 P C1 1, ISO 17632-T49 2 T1-A C1 A

JIS Z3313 T49T1-1CA-U

Features

1.The arc is soft and stable, less splashing, beautiful forming, good desagging, less soot, and has excellent welding process performance. Excellent low temperature impact performance.

Company & Factory

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | 0.18 | 2.00 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| AWS RULES | 0.12 | 1.75 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| EXAMPLE VALUE | 0.040 | 1.300 | 0.40 | 0.02 | 0.01 | 0.01 | 0.011 | 0.005 | 0.01 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 390 | 490-670 | AW | 27/-20 | 18 | ||||

| AWS RULES | 390 | 490-670 | AW | 27/-20 | 22 | ||||

| EXAMPLE VALUE | 480 | 550 | AW | 125/-20 | 28 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.2 | 1.4 | 1.6 | ||||

| VOLT | 23-32 | 24-36 | 25-40 | ||||

| AMP | 150-300 | 170-360 | 200-400 | ||||

| MM | 15-20 | 15-20 | 18-25 | ||||

| L/MIN | 15-25 | 15-25 | 15-25 |

NOTE:

H/W: horizontal position welding. O/W: over-head position welding

CERTIFICATION AUTHORITY:ABS/BV/CCS/DNV/GL/LR/NK/CE/JIS

TYPICAL CASES

Certificates

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | V |

| GB/T RULES | 0.18 | 2.00 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| AWS RULES | 0.12 | 1.75 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 0.08 |

| EXAMPLE VALUE | 0.040 | 1.300 | 0.40 | 0.02 | 0.01 | 0.01 | 0.011 | 0.005 | 0.01 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 390 | 490-670 | AW | 27/-20 | 18 | ||||

| AWS RULES | 390 | 490-670 | AW | 27/-20 | 22 | ||||

| EXAMPLE VALUE | 480 | 550 | AW | 125/-20 | 28 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.2 | 1.4 | 1.6 | ||||

| VOLT | 23-32 | 24-36 | 25-40 | ||||

| AMP | 150-300 | 170-360 | 200-400 | ||||

| MM | 15-20 | 15-20 | 18-25 | ||||

| L/MIN | 15-25 | 15-25 | 15-25 |

NOTE:

H/W: horizontal position welding. O/W: over-head position welding

CERTIFICATION AUTHORITY:ABS/BV/CCS/DNV/GL/LR/NK/CE/JIS