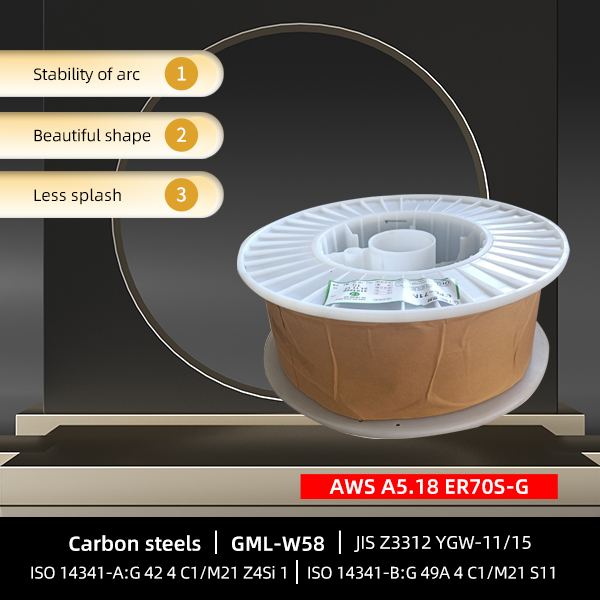

High Carbon steels MIG ER70S-G weld fabrication jointing

Application

Suitable FOR shipbuilding, bridge, construction and excavation welding applications, also used in high current finger plate butt welding, fillet welding and cross welding.

The standard we met: GB/T8110 G 49A4 C1/M21 S11 N , AWS A5.18 ER70S-G & A5.18M ER49S-G, ISO14341-A:G 42 4 C1/M21 Z4Si1, ISO 14341-B:G 49A 4 C1/M21 S11

JIS Z3312 YGW-11/15

Peculiarity

Environmental protection and health, and can avoid the adverse impact of copper on welding quality;

In addition to proper alloying elements such as Si and Mn, sufficient Ti elements are added to stabilize the arc and make the arc transition refined; The relative amount of splash and smoke is also significantly reduced;

Ti has the role of grain refinement of the weld pass, so that the toughness of the weld pass is greatly improved, and it can also play its superior performance in large flow welding.

Show details

Significantly improved resilience

High current welding can also play its superior performance

About us

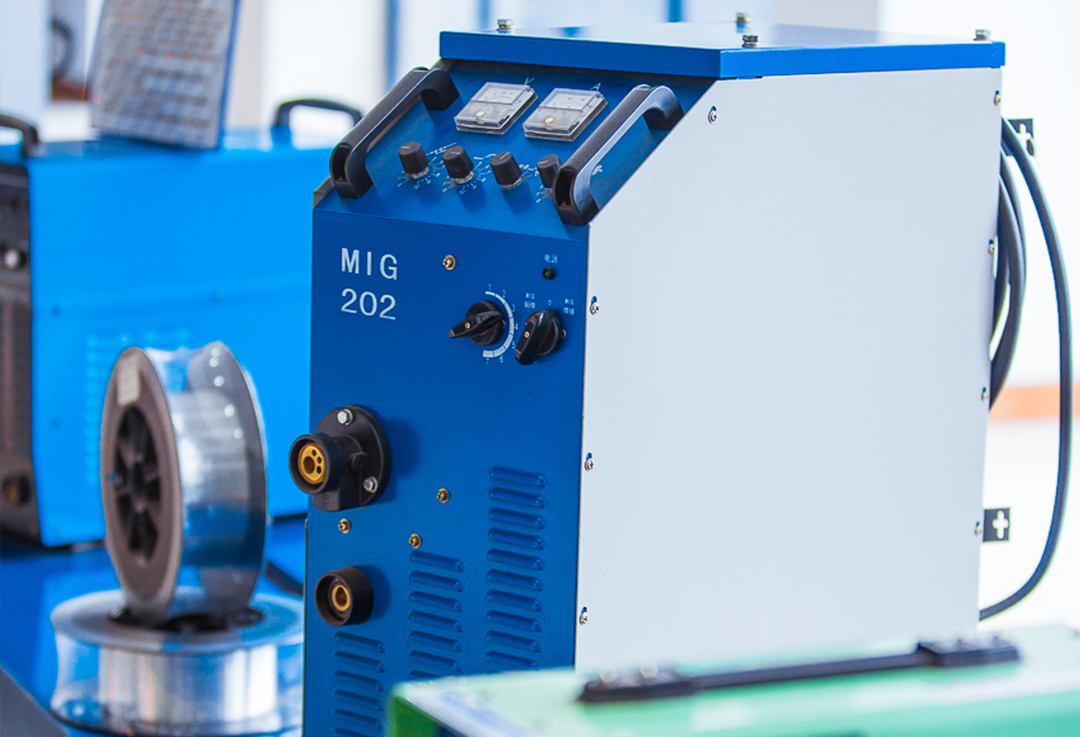

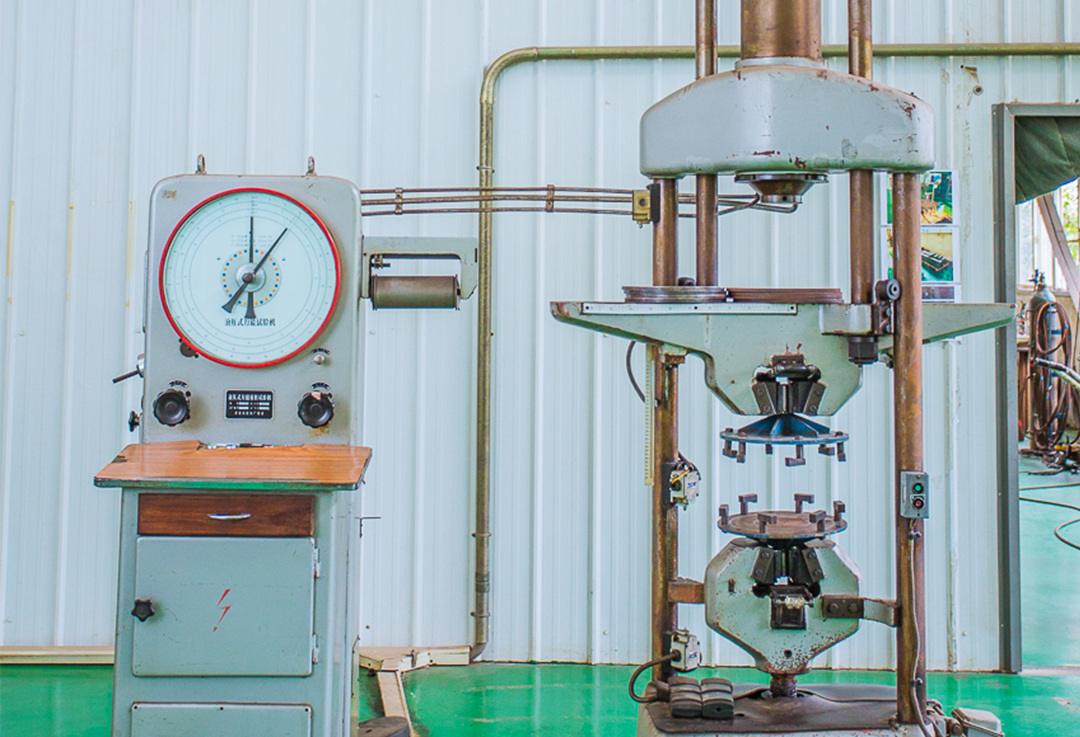

Factory fioor display

Application case

Canada LNG Project

Hainan Huasheng phenol recovery tower

Actual factory shooting

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Ti+Zr | P | S | Cu |

| GB/T RULES | 0.02-0.151 | 0.40-1.90 | 0.55-1.10 | - | - | - | 0.02-0.30 | 0.300 | 0.030 | 0.50 |

| AWS RULES | - | - | - | - | - | - | - | - | - | - |

| EXAMPLE VALUE | 0.055 | 1.500 | 0.85 | 0.03 | 0.02 | 0.01 | 0.18 | 0.013 | 0.010 | 0.02 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||

| GB/T RULES | 390 | 490-670 | AW | 27/-40 | 18 | |||||

| AWS RULES | 400 | 490 | AW | - | 22 | |||||

| EXAMPLE VALUE | 500 | 590 | AW | 78/-40 | 28 | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1 | 1.2 | 1.6 | |||||

| ELECTRICITY (Amp) |

H/W | 80-250 | 100-350 | 250-300 | ||||

| O/W | 70-120 | 80-150 | ||||||