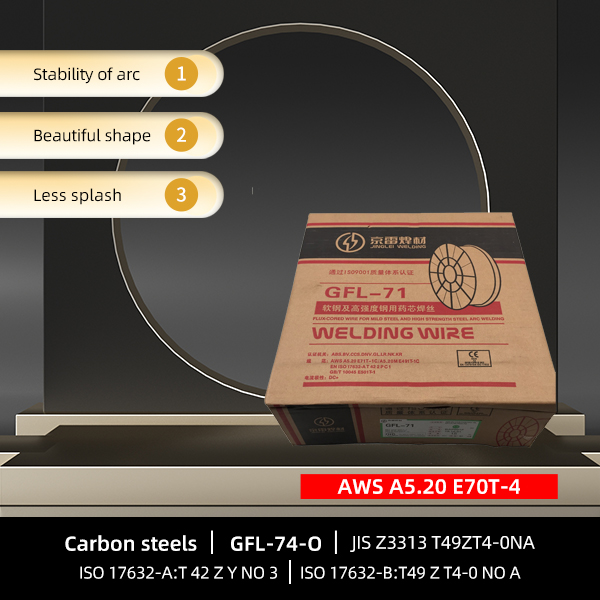

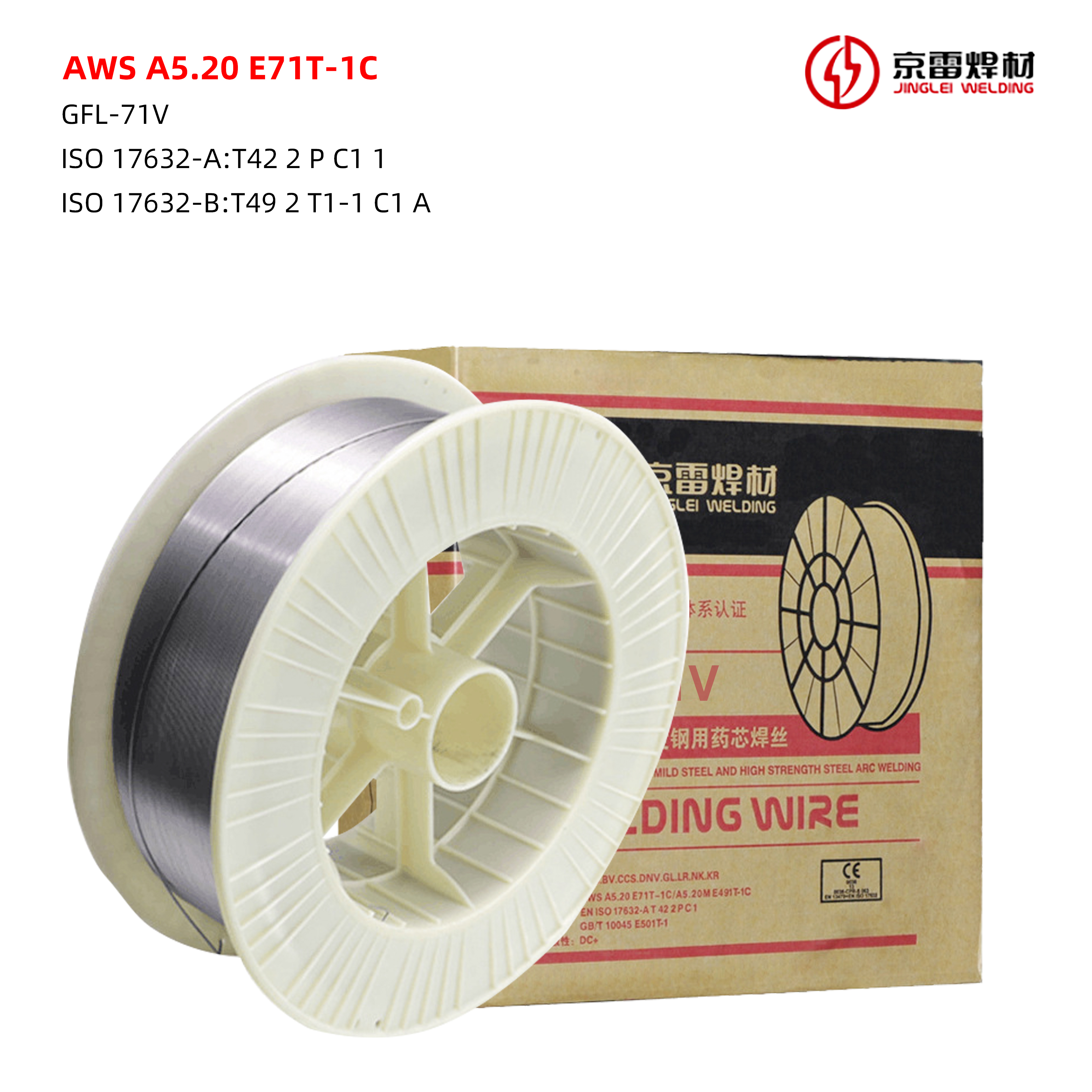

High Carbon steels Flux cored wire E70T-4 weld fabrication jointing

Application

Suitable for building structure, steel frame and other steel structure butt welding and fillet welding.

The standard we met: GB/T10045 T 49 Z T4-0 N A , AWS A5.20 E70T-4 & A5.20M E490T-4, ISO17632-A:T42 Z Y NO 3, ISO 17632-B:T49 Z-0 NO A,JIS Z3313 T49ZT4-0NA.

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | AI |

| GB/T RULES | 0.30 | 2.00 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 2.00 |

| AWS RULES | 0.30 | 1.75 | 0.30 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 1.80 |

| EXAMPLE VALUE | 0.220 | 0.550 | 0.30 | 0.03 | 0.02 | 0.01 | 0.013 | 0.002 | 1.5 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 390 | 490-670 | AW | - | 18 | ||||

| AWS RULES | 390 | 490-670 | AW | - | 22 | ||||

| EXAMPLE VALUE | 430 | 590 | AW | - | 25 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.4 | 2.8 | 3 | ||||

| VOLT | 24-32 | 24-35 | 24-35 | ||||

| AMP | 260-400 | 280-450 | 280-450 | ||||

| LENGTH:MM | 65-70 | 65-70 | 90-95 |

Peculiarity

Under the condition of base metal rust, oxidation and high sulfur content.

The use has good porosity resistance.

Welding pass forming beautiful, good slag removal.

Show details

Good desquamation

Beautiful shape

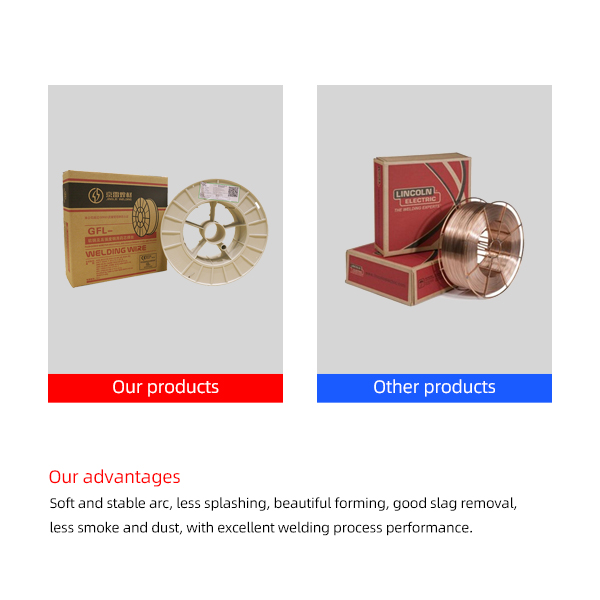

About us

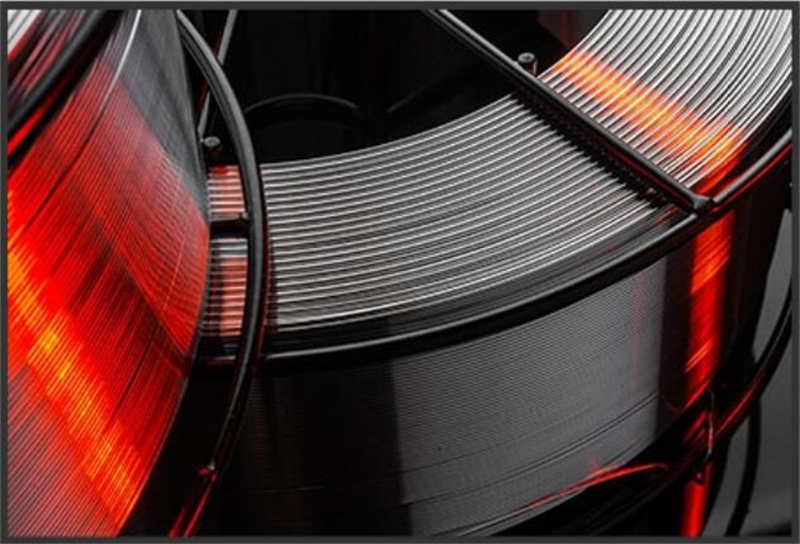

Factory fioor display

Application case

Three gates 2# are not motile

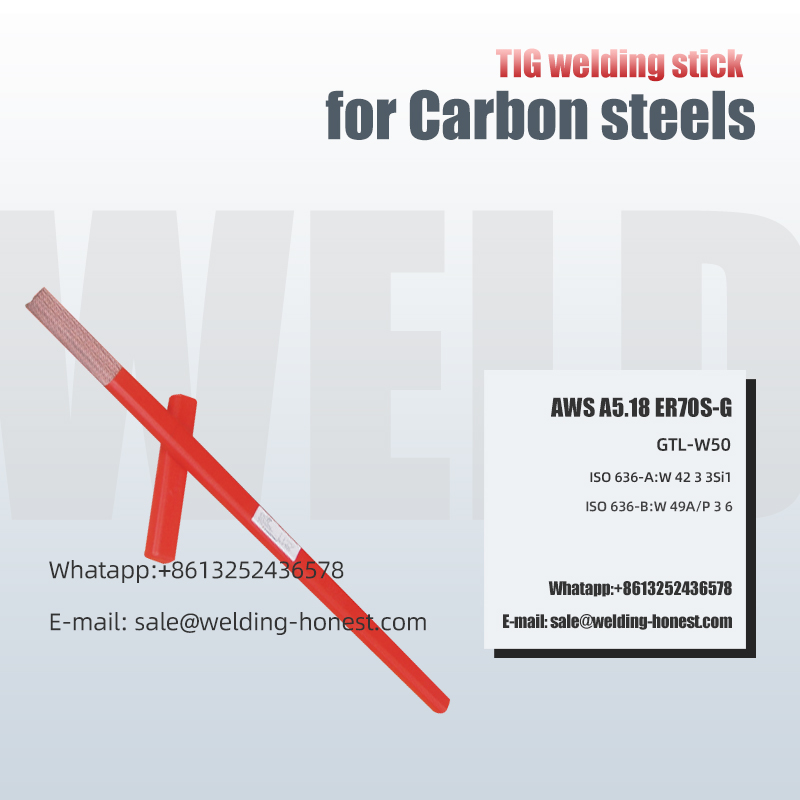

Welding materials for railway vehicles

Actual factory shooting

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | AI |

| GB/T RULES | 0.30 | 2.00 | 0.90 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 2.00 |

| AWS RULES | 0.30 | 1.75 | 0.30 | 0.20 | 0.50 | 0.30 | 0.030 | 0.030 | 1.80 |

| EXAMPLE VALUE | 0.220 | 0.550 | 0.30 | 0.03 | 0.02 | 0.01 | 0.013 | 0.002 | 1.5 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 390 | 490-670 | AW | - | 18 | ||||

| AWS RULES | 390 | 490-670 | AW | - | 22 | ||||

| EXAMPLE VALUE | 430 | 590 | AW | - | 25 | ||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.4 | 2.8 | 3 | ||||

| VOLT | 24-32 | 24-35 | 24-35 | ||||

| AMP | 260-400 | 280-450 | 280-450 | ||||

| LENGTH:MM | 65-70 | 65-70 | 90-95 |

Write your message here and send it to us