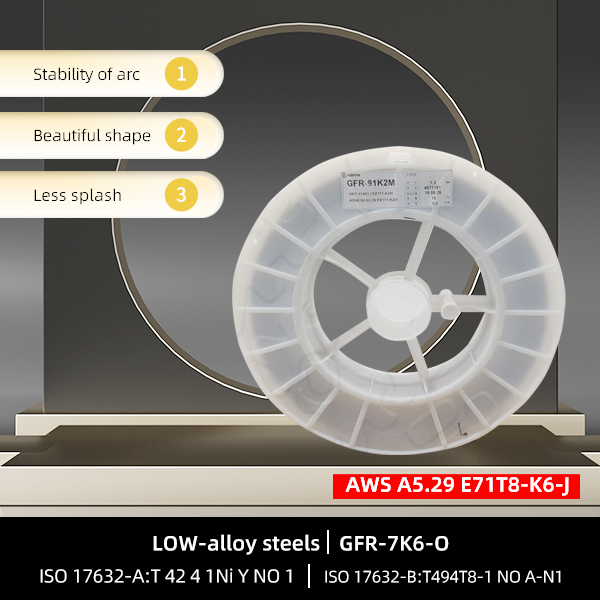

Low-alloy steels Flux cored wire E71T8-K6-J Soldering jointing

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Al |

| GB/T RULES | 0.12 | 1.75 | 0.80 | - | 0.3-1.0 | 0.35 | 0.03 | 0.03 | 1.80 |

| AWS RULES | 0.15 | 0.5-1.50 | 0.80 | 0.20 | 0.4-1.0 | 0.15 | 0.03 | 0.03 | 1.80 |

| EXAMPLE VALUE | 0.05 | 1.20 | 0.1 | 0.01 | 0.95 | 0.01 | 0.01 | 0.010 | 1 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Heat treatment°Cxh | |||||

| GB/T RULES | 390 | 490-670 | 27/-40 | 18 | AW | |||||

| AWS RULES | 400 | 490-620 | 47/-40 | 20 | AW | |||||

| EXAMPLE VALUE | 475 | 565 | 150/-40 | 27 | AW | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.6 | 2.0 | ||||||

| Volt | 15-20 | 15-20 | ||||||

| Amp | 180-250 | 180-300 | ||||||

| Dry extension length(mm) | 10-20 | 10-20 | ||||||

490MPa class alkaline self-protecting flux-cored wire.

Stable arc, less splash, beautiful forming, good slag removal, with excellent welding performance.

It has good low temperature impact performance.

-

China A heavy hydrogenation reactor

-

Qinghai Youjian Wunan Oilfield

-

Arctic LNG-2 project

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Al |

| GB/T RULES | 0.12 | 1.75 | 0.80 | - | 0.3-1.0 | 0.35 | 0.03 | 0.03 | 1.80 |

| AWS RULES | 0.15 | 0.5-1.50 | 0.80 | 0.20 | 0.4-1.0 | 0.15 | 0.03 | 0.03 | 1.80 |

| EXAMPLE VALUE | 0.05 | 1.20 | 0.1 | 0.01 | 0.95 | 0.01 | 0.01 | 0.010 | 1 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Heat treatment°Cxh | |||||

| GB/T RULES | 390 | 490-670 | 27/-40 | 18 | AW | |||||

| AWS RULES | 400 | 490-620 | 47/-40 | 20 | AW | |||||

| EXAMPLE VALUE | 475 | 565 | 150/-40 | 27 | AW | |||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 1.6 | 2.0 | ||||||

| Volt | 15-20 | 15-20 | ||||||

| Amp | 180-250 | 180-300 | ||||||

| Dry extension length(mm) | 10-20 | 10-20 | ||||||

Write your message here and send it to us