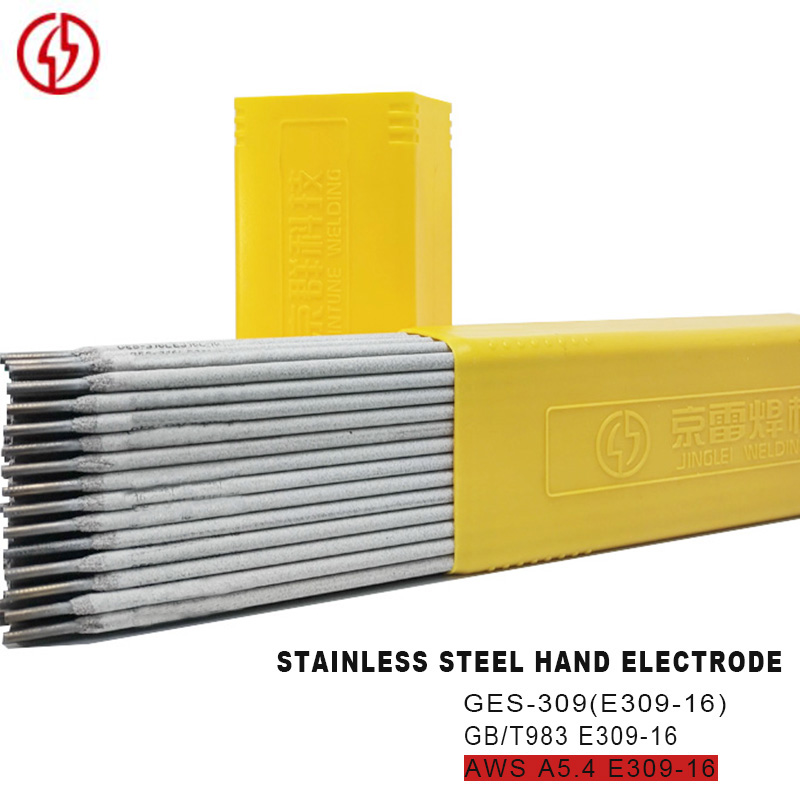

AWS E309-16 Stainless steels Solid wire Welding materials

Application&Standard&Note:

1. Suitable FOR STAINLESS STEEL AND CARBON STEEL OR LOW ALLOY steel DISsimilar STEEL WELDING, STAINLESS steel composite plate cladding WELDING, 308 SERIES STAINLESS STEEL SURFACING WELDING on carbon steel or low alloy STEEL.

2. The standard we met: GB/T983 E309-16, AWS A5.4 E309-16 & A5.4M E309-16, ISO3581-A:E(22 12) R 1 2, ISO3581-B:ES309-16

CHARACTERISTICS:

E309L-16 is an ultra-low carbon Cr23Ni13 stainless steel electrode used in rutile type pressure equipment. Cross – direct, can be used for all-position welding. The deposited metal has a low carbon content, so it can resist the inter crystalline corrosion caused by carbide precipitation when the stabilizer such as niobium and titanium is not contained.

Features

1. Titanium calcium stainless steel electrode, the main composition is 22% CR-12%Ni;

2. Stable arc, beautiful forming, fine ripples, few splashes, easy de-slagging, good fire resistance of drug skin, good stomatal resistance.

3. The weld metal contains more ferrite and has low crack sensitivity.

A302 is Cr23Ni13 stainless steel electrode with titanium calcium coating. The molten metal has good cracking resistance and oxidation resistance. Ac-dc dual use, good operation process performance. In order to improve the crack resistance and corrosion resistance of the molten metal, the Mo content in 16 was appropriately increased by about 1%.Stainless steel electrode is usually titanium calcium type and low hydrogen type two. Dc power supply is used for welding current as far as possible to overcome redness and depth of welding rod. Titanium calcium coating electrode is not suitable for full position welding, only suitable for flat welding and fillet welding; The electrode with low hydrogen coating can be used for full position welding.

Company & Factory

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.15 | 0.5-2.5 | 1.00 | 22.0-25.0 | 12.0-14.0 | 0.75 | 0.040 | 0.03 | 0.75 |

| AWS RULES | 0.15 | 0.5-2.5 | 1.00 | 22.0-25.0 | 12.0-14.0 | 0.75 | 0.040 | 0.03 | 0.75 |

| EXAMPLE VALUE | 0.046 | 1.35 | 0.77 | 24.5 | 12.6 | 0.38 | 0.028 | 0.003 | 0.13 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||||||

| GB/T RULES | - | 550 | - | - | 25 | |||||||||

| AWS RULES | - | 550 | - | - | 30 | |||||||||

| EXAMPLE VALUE | - | 617 | - | - | 38 | |||||||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||||

| ELECTRICITY (Amp) |

H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||||

PACKING DETAILES:

| SEPCIFICATION | LENGTH | PCS/1KG | WEIGHT/1KG | |||

| 2.0mm | 300mm | 79PCS | 2KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||

NOTE:

H/W: horizontal position welding

O/W: over-head position welding

Typical Cases

Certificate

Product composition and mechanical properties introduction

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.15 | 0.5-2.5 | 1.00 | 22.0-25.0 | 12.0-14.0 | 0.75 | 0.040 | 0.03 | 0.75 |

| AWS RULES | 0.15 | 0.5-2.5 | 1.00 | 22.0-25.0 | 12.0-14.0 | 0.75 | 0.040 | 0.03 | 0.75 |

| EXAMPLE VALUE | 0.046 | 1.35 | 0.77 | 24.5 | 12.6 | 0.38 | 0.028 | 0.003 | 0.13 |

MECHANICAL PROPERTY:

| PROPERTY | YIELD STRENGTH(MPa) | EXTENSION STRENGTH(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||||||

| GB/T RULES | - | 550 | - | - | 25 | |||||||||

| AWS RULES | - | 550 | - | - | 30 | |||||||||

| EXAMPLE VALUE | - | 617 | - | - | 38 | |||||||||

RECOMMENDED WELDING PARAMETERS:

| DIAMETERS SPECIFICATIONS(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||||

| ELECTRICITY (Amp) |

H/W | 50-75 | 70-95 | 80-120 | 110-160 | 160-190 | ||||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||||

PACKING DETAILES:

| SEPCIFICATION | LENGTH | PCS/1KG | WEIGHT/1KG | |||

| 2.0mm | 300mm | 79PCS | 2KG | |||

| 2.6mm | 300mm | 48PCS | 2KG | |||

| 3.2mm | 350mm | 27PCS | 5KG | |||

| 4.0mm | 350mm | 16PCS | 5KG | |||

| 5.0mm | 350mm | 12PCS | 5KG | |||

NOTE:

H/W: horizontal position welding

O/W: over-head position welding